×

×

PP fiber is a special material that can be used to make concrete strong and tough. In this article, we’re going to learn 5 of the great things about PP fiber in construction projects, how it can be used, and how it benefits the environment.

PP fiber is a synthetic product added to concrete to make it stronger and less crack-prone. Just adding a small amount of PP fiber into the concrete mixes would bond it and prevent it from cracking. That means that buildings made with PP fiber are safer, and they last longer.

And one of the best things about PP fiber in concrete is that it helps make buildings and roads last longer. They are less susceptible to wear and tear over time, even in harsh weather or heavy traffic. With PP fiber mixed in concrete, builders can construct buildings that require less fixing, and can use it as a time and cost-saving measure.

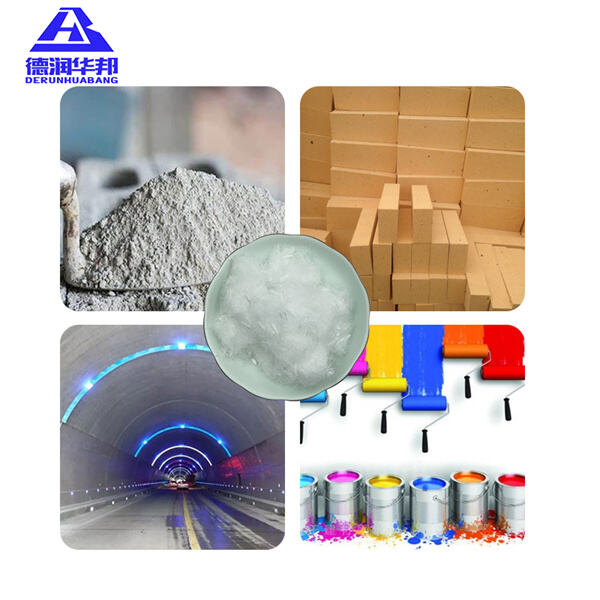

PP fiber can be applied to numerous construction applications, including foundations, roads, bridges and tunnels. When incorporated into concrete, PP fiber helps engineers build robust, pliable structures that are resistant to cracking. This makes PP fiber an ideal choice for applications that require high security and durability.

PP Fiber added to the concrete is beneficial to the tensile strength. Tensile strength is the ability of a material to with stand breaking when stretched or pulled. With PP fiber, builders could develop structures that withstand bending and stretching more effectively. This is key for applications that require both flexibility and strength.

PP fiber is also an environmentally sound choice in addition to its many practical benefits. Because it’s a synthetic, it can be produced with less damage to nature. Its use of PP fiber enables less pollution from the building industry and more environmentally friendly usable construction work.

Huayang provides plenty non-metal mineral products, as products, such as Pp fiber, mica, bentonite, graphite, tourmaline, iron oxide so. our province is in all kinds of mineral sources, quilted producing, processing, laboratory, storage workshop, production line over 20.

We are professional provider minerals. teams focus on product design development quality control, inspection and design as well as business management. Please contact if you have any suggestions regarding products. We look Pp fiber to working with and providing you with high-quality products.

Shijiazhuang Huabang Mineral Products Co., Ltd. a building materials enterprise integrating production, processing, sales. The company situated in Shikan Industrial Zone, Ciyu Town, Lingshou County, Hebei Province 50km away Shijiazhuang capital of Hebei Pp fiber, 260km away from Beijing, which conveniently located transport, communications abundant mineral resources.

products have been certified ISO 9001 technical qualification certification are shipped to more than 70 countries, with more than 1,000 buyers Southeast Asia, Eastern Europe, America... products have been certified by ISO 9001 technical qualification Pp fiber have been exported to over 70 countries, more than 1000 customers and regions throughout Southeast Asia, Eastern Europe America...