Η διατομίτης προκύπτει ως ένα φυσικό, φιλικό προς το περιβάλλον υλικό που συνδέει τη βιώσιμη ανάπτυξη με την οικονομία της ανακύκλωσης, προσαρμόζοντας με καινοτομία τις διάφορες απαιτήσεις της πράσινης υποδομής, των αντιφλεγόντων υλικών και της φιλτραρίσματος στη βαφή υφασμάτων. Σε αντίθεση με τα συνθετικά υλικά, τα οποία βασίζονται σε μη ανανεώσιμους πόρους όπως το πετρέλαιο για την παραγωγή τους ή εκπέμπουν τοξικές πτητικές ενώσεις κατά τη διάρκεια της παραγωγής, η διατομίτης προέρχεται από απολιθωμένα διάτομα—μικροσκοπικούς μονοκύτταρους υδρόβιους οργανισμούς με κυτταρικά τοιχώματα από πυρίτιο που πολλαπλασιάστηκαν στους αρχαίους ωκεανούς και λίμνες και απολιθώθηκαν εκατομμύρια χρόνια κάτω από ιζηματογενή πίεση. Αυτή η μοναδική προέλευση της προσδίδει εγγενή πορώδη δομή—κάθε σωματίδιο γεμάτο με μικρές συνδεδεμένες πορώδεις δομές από πυρίτιο—και ισχυρή ικανότητα προσρόφησης που ξεπερνά πολλά συνθετικά προσροφητικά. Αυτά τα χαρακτηριστικά δεν τη διαφοροποιούν μόνο από τα συμβατικά βιομηχανικά υλικά, αλλά την καθιστούν και οικονομική εναλλακτική λύση σε ακριβά συνθετικά πρόσθετα. Ως βασικό συστατικό στον καθαρισμό του αέρα, στη φιλτραρίσματος του νερού και στην εσωτερική ανακαίνιση, η διατομίτης ξεπερνά τους μονολειτικούς ρόλους για να γίνει πολυλειτουργική λύση που συνδυάζει φυσικές ιδιότητες, λειτουργική απόδοση και περιβαλλοντική υπευθυνότητα, ενσωματώνοντας ομαλά στις σύγχρονες βιομηχανικές αλυσίδες με οικολογική συνείδηση.

Η πορώδης βάση του διατομίτη συνδυάζει φυσική αφθονία και οικολογική αρμονία, με κοιτάσματα διασπαρμένα σε όλους τους επιμέρους ηπείρους για εξασφάλιση σταθερής προμήθειας. Ο διατομίτης δημιουργείται μέσω δεκάδων εκατομμυρίων ετών συσσώρευσης διατόμων σε θαλάσσιες ή λιμναίες λεκάνες, όπου συγκεκριμένες περιβαλλοντικές συνθήκες—όπως σταθερή θερμοκρασία, επαρκής ηλιακός φωτισμός και πλούσιο σε θρεπτικά συστατικά νερό—προάγουν τη μαζική ανάπτυξη διατόμων. Τα κοιτάσματα διαφέρουν ανάλογα με το περιβάλλον για να καλύπτουν διαφορετικές νέες ανάγκες: ο θαλάσσιος διατομίτης, που βρίσκεται σε ιζήματα νορδικών φιορδών και σε θαλάσσια ράφια της Ανταρκτικής, επωφελείται από το κρύο και καθαρό θαλάσσιο περιβάλλον για να σχηματίσει λεπτότερους, πυκνότερους πόρους και ισχυρότερη ικανότητα προσρόφησης, κάνοντάς τον ιδανικό για καθαρισμό αέρα, υψηλής ακρίβειας φιλτράρισμα νερού και φιλτράρισμα βαφών στη βιομηχανία υφασμάτων· ο λιμναίος διατομίτης, που συσσωρεύεται σε λίμνες του οροπεδίου των Άνδεων της Νοτίου Αμερικής (με χαμηλή περιεκτικότητα σε άλατα) και σε παράκτιες περιοχές της Ασίας, διαθέτει μεγαλύτερους, συνδεδεμένους μεταξύ τους πόρους και ανώτερη θερμομόνωση, καθιστώντας τον κατάλληλο για πράσινη υποδομή και αντιφλεγόμενα υλικά. Η εξόρυξη συμμορφώνεται με αυστηρά φιλικά προς το περιβάλλον πρότυπα που επιβάλλονται από περιφερειακούς περιβαλλοντικούς φορείς: χρησιμοποιείται αποκλειστικά επιφανειακή εξόρυξη για να αποφευχθεί η βαθιά γεωλογική διαταραχή που θα μπορούσε να βλάψει υδροφορείς ή τα οικοσυστήματα του εδάφους, ενώ οι εξορυγμένες περιοχές υπόκεινται σε συστηματική οικολογική αποκατάσταση—φυτεύοντας ενδημικά ξηρόφιτα φυτά για τη σταθεροποίηση των ξηρών εξορυκτικών ζωνών, αποκαθιστώντας υδρόβια χλωρίδα κοντά σε λιμναία κοιτάσματα και εγκαθιστώντας σταθμούς μακροπρόθεσμης παρακολούθησης για την παρακολούθηση της ποιότητας του εδάφους και του νερού. Η αρχή της κυκλικής οικονομίας εφαρμόζεται εντατικά στην επαναχρησιμοποίηση αποβλήτων: τα χονδρά υπολείμματα από τον καθαρισμό του διατομίτη, τα οποία διατηρούν ακόμη μερικώς την πορώδη δομή τους, αλέθονται σε ακανόνιστα κοκκώδη υλικά για θερμομόνωση σε πράσινες υποδομές· η λεπτή σκόνη που παράγεται κατά την αλέση και την ταξινόμηση ανακυκλώνεται ως πρόσθετο σε αντιφλεγόμενα υλικά, ελαχιστοποιώντας όχι μόνο τη σπατάλη πόρων αλλά και την πίεση στα χώρους υγειονομικής ταφής.

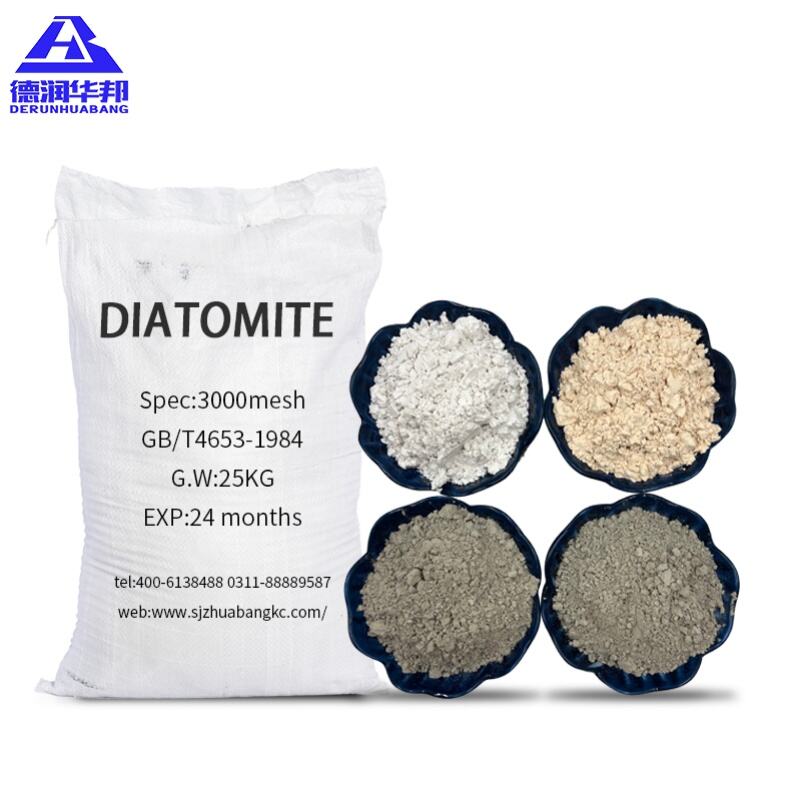

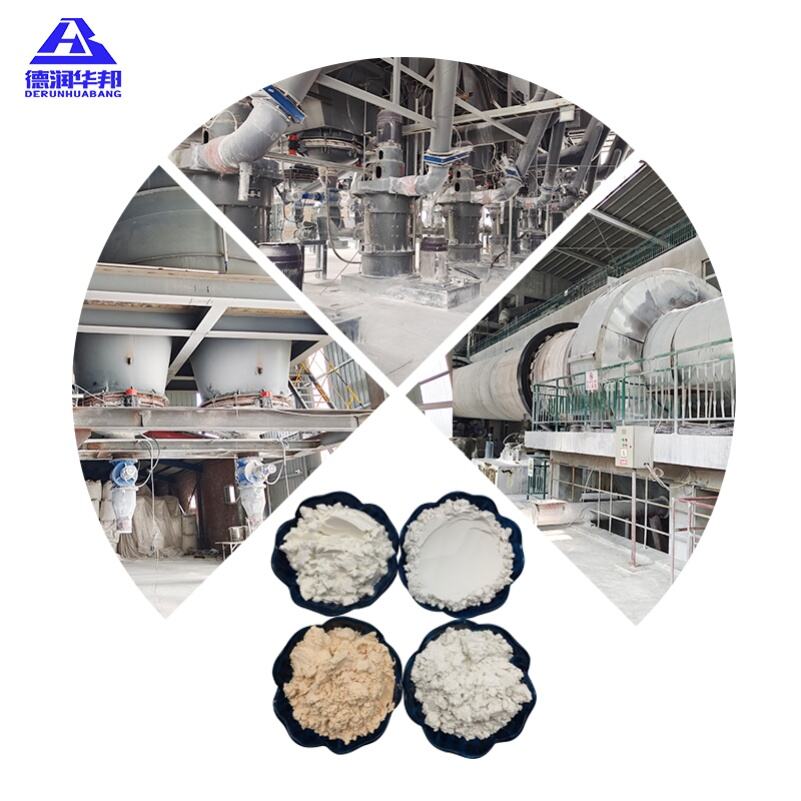

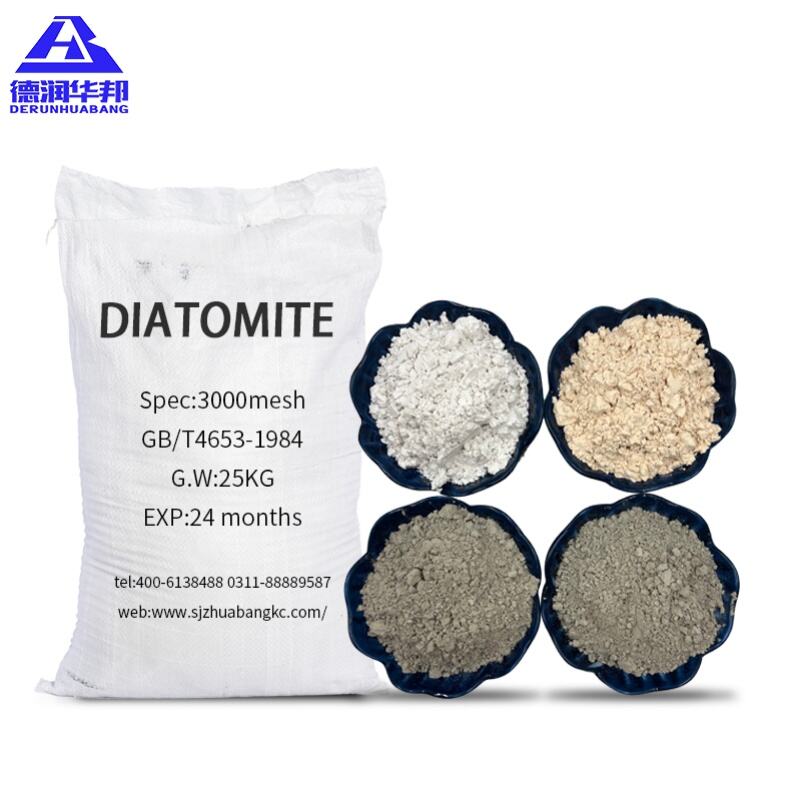

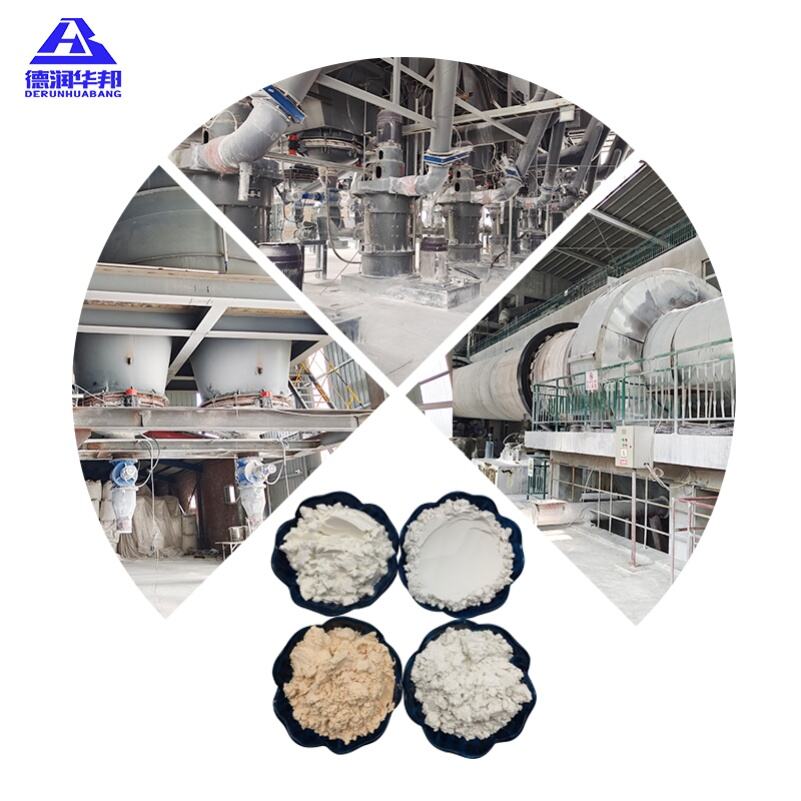

Οι διεργασίες παραγωγής της διατομίτη επικεντρώνονται στη διατήρηση των βασικών ιδιοτήτων και στη μείωση του περιβαλλοντικού αντίκτυπου, όπου κάθε βήμα ρυθμίζεται για να αποφεύγεται η βλάβη της ευάλωτης δομής του διοξειδίου του πυριτίου. Η επεξεργασία βασίζεται σε βέλτιστες φυσικές μεθόδους για τη διατήρηση της πορώδους δομής και της ικανότητας προσρόφησης: η ψύξη με ροή αέρα χαμηλής θερμοκρασίας (που λειτουργεί με ελεγχόμενες περιστροφικές ταχύτητες για να αποφεύγεται η υπερβολική θραύση των σωματιδίων) αντικαθιστά την επεξεργασία υψηλής θερμοκρασίας, η οποία θα τήξει και θα καταρρεύσει τους ευάλωτους πόρους του διοξειδίου του πυριτίου, ελέγχοντας τη δύναμη σύγκρουσης των σωματιδίων· η ταξινόμηση με αέρα χρησιμοποιεί πολυστάδια διαχωρισμό με κυκλώνα για την ταξινόμηση των σωματιδίων ανά μέγεθος χωρίς χημικά αντιδραστήρια — πολύ λεπτή σκόνη (αρκετά λεπτή για να περνά από λεπτά κόσκινα) για φιλτράρισμα χρωστικών στην υφαντουργία και φίλτρα αέρα υψηλής απόδοσης, μεσαία σκόνη για λεία επιχρίσματα εσωτερικής ανακαίνισης, χονδρές κόκκινες μορφές για μονωτικά σκληρά σε πράσινη υποδομή. Η υψηλής καθαρότητας διατομίτης που χρησιμοποιείται για φιλτράρισμα νερού και χρωστικών στην υφαντουργία υποβάλλεται σε υγρή ψύξη κλειστού κυκλώματος: ανακυκλωμένο αποϊονισμένο νερό χρησιμοποιείται ως μέσο ψύξης για να αποφεύγεται η μόλυνση, ενώ το νερό επεξεργάζεται μέσω καθίζησης και ανταλλαγής ιόντων πριν επαναχρησιμοποιηθεί σε επόμενες παρτίδες, αποφεύγοντας εντελώς την απόρριψη λυμάτων. Μια καινοτόμος τεχνολογία ενεργοποίησης με κενό ενισχύει περαιτέρω την ικανότητα προσρόφησης, αφαιρώντας απαλά τις οργανικές προσμίξεις που είναι παγιδευμένες στους πόρους κατά την απολίθωση, ανοίγοντας τους φραγμένους αγωγούς χωρίς να αλλάζει η δομή των πόρων. Τα υβριδικά συστήματα ξήρανσης ανέμου-ηλιακής ενέργειας χρησιμοποιούνται ευρέως στο τελικό στάδιο επεξεργασίας, αντικαθιστώντας τη θέρμανση με κάρβουνο ή φυσικό αέριο και μειώνοντας σημαντικά το αποτύπωμα άνθρακα. Οι διεργασίες αυτές δεν διατηρούν μόνο τις φυσικές οικολογικές ιδιότητες της διατομίτης, αλλά επίσης βελτιστοποιούν την απόδοσή της για στοχευμένες νέες εφαρμογές, εξασφαλίζοντας συνέπεια σε όλες τις παρτίδες.

Οι βασικές ιδιότητες της Διατομίτη την καθιστούν αναντικατάστατη σε πολλές βιομηχανίες, με κάθε χαρακτηριστικό να προέρχεται από τη μοναδική του δομή πορώδους διοξειδίου του πυριτίου. Η πορώδης δομή — που χαρακτηρίζεται από αμέτρητους μικροσκοπικούς ενωμένους πόρους που σχηματίζουν ένα τρισδιάστατο δίκτυο και μια τεράστια εσωτερική επιφάνεια (συχνά εκατοντάδες τετραγωνικά μέτρα ανά γραμμάριο) — επιτρέπει εξαιρετική ικανότητα προσρόφησης: παγιδεύει ενεργά πτητικές οργανικές ενώσεις όπως η φορμαλδεΰδη και το βενζόλιο από τον εσωτερικό αέρα, συλλαμβάνει σκόνη, γύρη και λεπτά αιωρούμενα σωματίδια από βιομηχανικές εκπομπές, απορροφά βαρέα μέταλλα όπως μόλυβδος και υδράργυρος, μικρορύπανση και μόρια χρωστικών από υφαντουργικά απόβλητα νερά, και ενισχύει την αντίσταση στη φωτιά με την παγίδευση θερμότητας και την επιβράδυνση της μεταφοράς θερμότητας. Η αναπνευστικότητα και ο κανονισμός της υγρασίας, που οφείλονται στην τριχοειδή δράση στο πορώδες δίκτυο, επιτυγχάνουν δυναμικό έλεγχο: σε εσωτερικούς χώρους, απορροφά την περίσσεια υγρασίας κατά τη διάρκεια βροχερών περιόδων ή σε περιοχές υψηλής υγρασίας για να αποτρέψει την ανάπτυξη μούχλας στους τοίχους και τη στρέβλωση των επίπλων, και σταδιακά απελευθερώνει την αποθηκευμένη υγρασία όταν ο αέρας γίνεται ξηρός (όπως σε θερμαινόμενους χώρους τον χειμώνα), διατηρώντας ένα άνετο εύρος σχετικής υγρασίας. Η χημική σταθερότητα, που απορρέει από την αδρανή σύνθεση του διοξειδίου του πυριτίου, εξασφαλίζει μακροχρόνια ανθεκτικότητα: αντιστέκεται στη διάβρωση από βιομηχανικές χρωστικές, ασθενή οξέα και αλκάλια, καθιστώντας την κατάλληλη για σκληρά περιβάλλοντα όπως εγκαταστάσεις βαφής υφασμάτων και συστήματα επεξεργασίας βιομηχανικών αποβλήτων, καθώς και για μακροχρόνια χρήση σε εσωτερικούς χώρους χωρίς αποχρωματισμό. Η θερμομόνωση, που προέρχεται από τον ακίνητο αέρα που παγιδεύεται μέσα στους πόρους της, προσθέτει σημαντική αξία σε πράσινες υποδομές και αντιφλεγόμενα υλικά — μειώνοντας τη μεταφορά θερμότητας μέσω τοίχων και οροφών και επιβραδύνοντας τη διάδοση της φλόγας με τη μόνωση εύφλεκτων υλικών.

Η διατομίτης ξεχωρίζει σε πολλαπλά νέα εφαρμοστικά σενάρια, με πραγματικά έργα που αποδεικνύουν την ευελιξία και τα πλεονεκτήματα απόδοσής της. Η πράσινη υποδομή αξιοποιεί τη θερμομόνωση και την αναπνευστικότητά της σε πρακτικές εφαρμογές: σε βόρειες χώρες, υλικά συνθετικής υπόστρωσης βασισμένα σε διατομίτη χρησιμοποιούνται στην κατασκευή αυτοκινητοδρόμων για τη μείωση της θερμικής τάσης λόγω κύκλων παγετού-αποπάγωσης, αποτρέποντας τη ρωγμάτωση του οδοστρώματος σε ακραίες χειμερινές συνθήκες· πινακίδες θερμομόνωσης εξωτερικών τοίχων που περιέχουν διατομίτη εφαρμόζονται ευρέως σε κατοικιακές περιοχές της Ασίας, μείωση της κατανάλωσης ενέργειας των κτιρίων με την αποτροπή της μεταφοράς θερμότητας και σημαντική μείωση του φορτίου κλιματισμού. Η εσωτερική ανακαίνιση ενσωματώνει τη διατομίτη στους χώρους καθημερινής ζωής: επιχρίσματα διατομίτη εφαρμόζονται σε υπνοδωμάτια και παιδικά δωμάτια λόγω της ικανότητάς τους για καθαρισμό του αέρα, απορροφώντας ενεργά φορμαλδεΰδη που εκλύεται από ξύλινα έπιπλα και κολλώδη υλικά των χαλιών· διακοσμητικοί λίθοι που περιέχουν διατομίτη προσφέρουν μια ποικιλία φυσικών υφών — από λεία μορφή μοιάζουσα με μάρμαρο, κατάλληλη για σύγχρονα σαλόνια, έως κοκκώδη υφή μοιάζουσα με αμμόλιθο, η οποία ταιριάζει σε παραδοσιακά ρυθμικά στυλ. Η καθαρισμός του αέρα την αξιοποιεί σε περιβάλλοντα υψηλής ρύπανσης: φίλτρα βασισμένα σε διατομίτη σε εκτυπωτικές εγκαταστάσεις παγιδεύουν πτητικές οργανικές ενώσεις και σκόνη μελανιού, βελτιώνοντας την ποιότητα του αέρα στο εργαστήριο και μειώνοντας την έκθεση των εργαζομένων σε επιβλαβείς σωματίδια· βιομηχανικά φίλτρα τη χρησιμοποιούν σε εγκαταστάσεις επεξεργασίας μετάλλων για την αφαίρεση σκόνης οξειδίων μετάλλων από τις βιομηχανικές εκπομπές. Η φιλτράριση νερού και η φιλτράριση βαφών υφασμάτων χρησιμοποιούν κοκκώδη διατομίτη ως βασικό μέσο σε πολυστάδια συστήματα: σε εργοστάσια υφασμάτων, καθαρίζει τα απόβλητα νερά που περιέχουν υπολείμματα αντιδραστικών βαφών, επιτρέποντας την ανακύκλωση του νερού για την παραγωγή· σε εγκαταστάσεις επεξεργασίας νερού σε αγροτικές περιοχές, βελτιώνει τη διαύγεια του πόσιμου νερού απορροφώντας μικρο-ακαθαρσίες. Τα αντιπυρικά υλικά αποτελούν μια σημαντική νέα εφαρμογή: η διατομίτης, αναμεμιγμένη με φιλικά προς το περιβάλλον αντιπυρικά, δημιουργεί επικαλύψεις για ξύλινες κατασκευές σε δημόσια κτίρια, επιβραδύνοντας την καύση και μειώνοντας την εκπομπή καπνού, κάτι που δίνει περισσότερο χρόνο για εκκένωση σε καταστάσεις έκτακτης ανάγκης.

Ο έλεγχος ποιότητας της διατομίτη προσαρμόζεται σε συγκεκριμένες νέες εφαρμογές, με αυστηρά πρωτόκολλα δοκιμών για εξασφάλιση σταθερής και αξιόπιστης απόδοσης. Για βαθμούς επεξεργασίας αέρα και νερού, διενεργούνται δοκιμές απορροφητικής απόδοσης υπό προσομοιωμένες συνθήκες λειτουργίας, όπως η έκθεση δειγμάτων διατομίτη σε διαλύματα χρωστικών γνωστής συγκέντρωσης για σενάρια φιλτραρίσματος χρωστικών υφασμάτων—προκειμένου να μετρηθεί η ικανότητα παγίδευσης ρύπων· η ανάλυση μεγέθους πόρων πραγματοποιείται με μικροσκοπική απεικόνιση για διασφάλιση ότι οι πόροι έχουν μέγεθος ανάλογο με αυτό των στόχος ρύπων (μικρότεροι πόροι για μόρια χρωστικών, μεγαλύτεροι πόροι για αιωρούμενα στερεά). Για αντιπυρικά υλικά, διενεργούνται δοκιμές κατακόρυφης καύσης σε ελεγχόμενα εργαστήρια για αξιολόγηση του ρυθμού διάδοσης της φλόγας και της πυκνότητας του καπνού, ενώ δοκιμές θερμικής σταθερότητας εκθέτουν τα δείγματα σε υψηλές θερμοκρασίες για μεγάλα χρονικά διαστήματα προκειμένου να επαληθευτεί η αντοχή. Για υλικά πράσινης υποδομής, οι δοκιμές θερμικής αγωγιμότητας μετρούν τους ρυθμούς μεταφοράς θερμότητας σε θάλαμους με ελεγχόμενο κλίμα για επιβεβαίωση των ενεργειακά εξοικονομητικών επιδόσεων, ενώ οι δοκιμές αναπνευστότητας προσομοιώνουν υγρές και ξηρές περιόδους για παρακολούθηση των ρυθμών απορρόφησης και αποβολής υγρασίας. Για το φιλτράρισμα χρωστικών υφασμάτων, οι δοκιμές ρυθμού απορρόφησης χρωστικών παρακολουθούν πόσο γρήγορα απομακρύνονται οι ρύποι, ενώ οι δοκιμές ροής μετρούν τον ρυθμό ροής νερού για διασφάλιση ότι η αποδοτικότητα φιλτραρίσματος δεν θα επηρεάσει την ταχύτητα παραγωγής. Τα υπολείμματα ανακύκλωσης υποβάλλονται σε αυστηρές διεργασίες καθαρισμού—η μαγνητική διαχωρισμός αφαιρεί μεταλλικές προσμίξεις που συλλέχθηκαν κατά τη διάρκεια της εξόρυξης, ενώ οι δοκιμές ομοιομορφίας μεγέθους σωματιδίων διασφαλίζουν σταθερή απόδοση και υποβάλλονται στις ίδιες δοκιμές απόδοσης με την πρωτογενή διατομίτη για να πληρούν τα βιομηχανικά πρότυπα. Πολλοί κατασκευαστές επιδιώκουν επίσης πιστοποιήσεις βιωσιμότητας από ανεξάρτητους φορείς για να επιβεβαιώσουν ότι οι διεργασίες παραγωγής συμφωνούν με διεθνή κριτήρια βιωσιμότητας, δημιουργώντας έτσι εμπιστοσύνη μεταξύ των βιομηχανικών πελατών.

×

×