Kaolin Powder is naturally occurring non-metallic mineral centered on kaolinite, boasting soft texture, fine plate-like particles and synergistic physical-chemical properties that work together to unlock diverse industrial value. Plate-like structure—with thin, flat morphology—enables particles to overlap and interlock tightly in formulations, creating dense networks that enhance stability, mechanical strength and barrier performance of end products. This unique particle shape also contributes to its excellent suspension ability, a key trait for liquid-based formulations. Core traits include inherent whiteness that avoids discoloring end products—critical for light-colored or transparent materials like clear sealants or light-toned polymers—excellent plasticity that aids in semi-solid shaping of sealants and adhesives (allowing them to conform to irregular surfaces), stable chemical inertness that resists reactions with common industrial ingredients like resins, solvents and plasticizers, and strong suspension ability that maintains uniform dispersion in liquid systems, preventing settling or stratification during long-term storage. These qualities make it cornerstone of specialized industrial formulations, as it integrates seamlessly without altering core functions or chemical nature of base materials. Unlike minerals confined to narrow uses, kaolin powder can be customized via targeted washing, calcining or surface modification to meet precise needs of different sectors—whether enhancing whiteness for electronic packaging or boosting thermal stability for refractories—allowing it to integrate seamlessly into diverse production chains, acting as silent enhancer that elevates product performance without disrupting base systems.

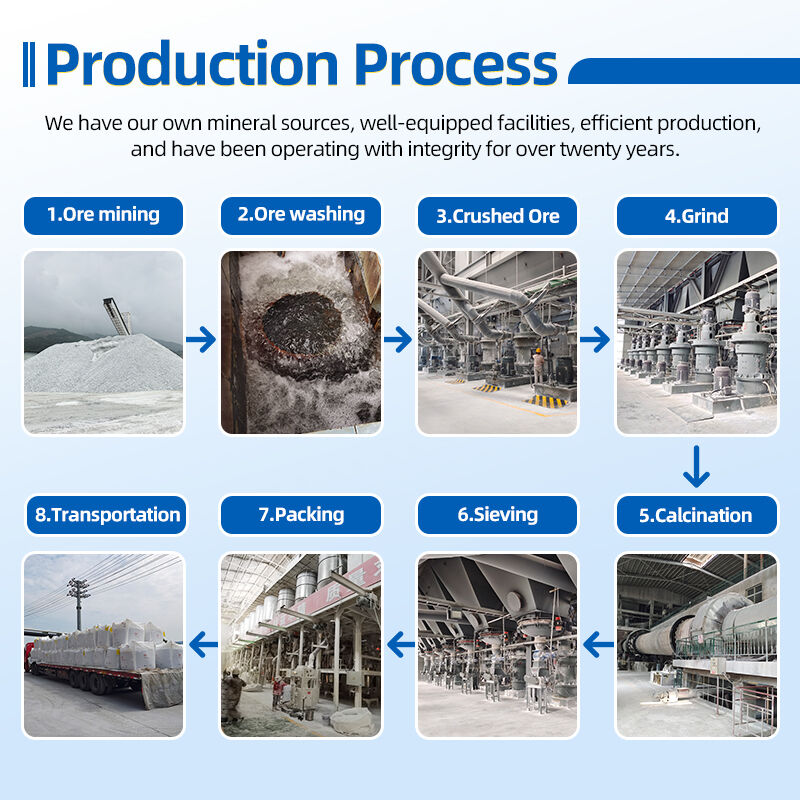

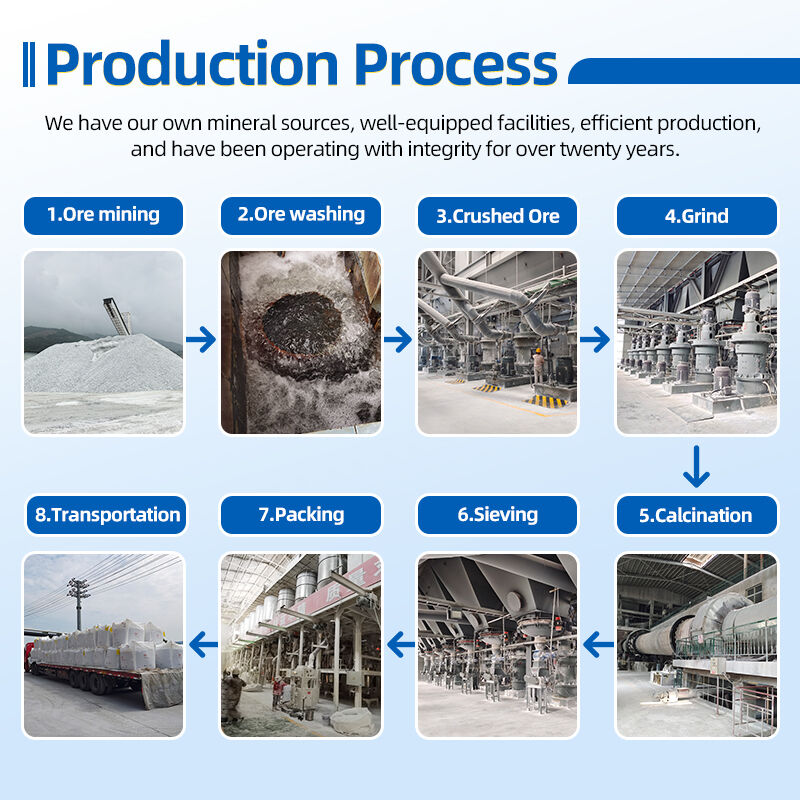

Processing techniques are tailored to unlock specific functionalities of kaolin powder for different sectors, bridging natural properties with precise industrial demands. Washing is foundational step for applications requiring high purity and consistent whiteness: raw ore is first crushed into small fragments, then mixed with water to form fine slurry. This slurry is passed through gravity separation tanks or centrifugal separators to remove heavier impurities, coarse grains and organic contaminants—such as plant residues or soil particles—that could compromise performance. The resulting refined slurry is then dried to form powder with enhanced purity and whiteness, ideal for formulations demanding uniform color, like electronic packaging materials or light-colored adhesives. Calcining is critical for high-temperature applications: particles are heated in kilns under strictly controlled conditions—with carefully regulated heating and cooling rates—to eliminate trapped moisture and organic matter. This process induces subtle changes in crystal structure, transforming kaolin into metakaolin, which boasts significantly boosted hardness, thermal stability and opacity. This treated kaolin powder excels in refractory materials and high-heat polymer products exposed to harsh environments, as it resists deformation and discoloration under extreme temperatures. Surface modification is key for compatibility with organic matrices: particles are coated with coupling agents like silane or titanate derivatives in specialized mixers, creating a thin layer that improves bonding with resins and polymers. This modification prevents particle agglomeration (a common issue with mineral fillers) and maximizes reinforcing effects in composite materials by ensuring uniform dispersion. Each processing step is meticulously adjusted based on target industry—from particle size distribution to surface treatment type—ensuring kaolin powder delivers optimal performance in every application.

Adhesive and sealant industry relies on kaolin powder as functional filler to solve key formulation challenges that directly affect application ease and long-term performance. It precisely adjusts viscosity to ideal levels—thickening liquid adhesives just enough to prevent excessive flow (sagging) during vertical application on walls, ceilings or vertical panels, while maintaining smoothness for precise bonding of small or irregular components like electronic parts, decorative trims or delicate machinery components. Fine particle size (often falling into micrometer range) and strong suspension ability work in tandem to maintain uniform texture during long-term storage—whether in drums, buckets or tubes—avoiding sedimentation that would create lumps, uneven bonding strength or inconsistent application. Kaolin powder enhances bonding strength through dual mechanisms: its fine particles penetrate tiny pores and gaps in substrates—whether porous wood, smooth metal or non-porous plastic—forming mechanical interlocks, while its surface (especially when modified) forms weak chemical bonds with substrate surfaces, creating tight bonds resistant to peeling, shearing and environmental erosion from moisture, humidity or common chemicals. In construction sealants—used for gaps around windows, doors or expansion joints—it boosts flexibility and weather resistance, allowing sealants to stretch and contract with seasonal temperature changes (from freezing winters to hot summers) and structural movements (like building settling or minor seismic activity) without cracking or losing adhesion. This flexibility creates reliable barrier that protects buildings from water infiltration (which can cause mold growth or structural damage), air leakage (which increases energy costs) and dust intrusion, preserving indoor comfort and structural integrity for years.

Refractory materials sector values kaolin powder for its exceptional thermal stability and high melting point, which make it irreplaceable component in heat-resistant formulations designed to withstand extreme industrial conditions. It is mixed with alumina, magnesia and other heat-resistant minerals in precise ratios to form specialized blends for refractory bricks, castables (pourable refractory materials that harden in place) and furnace linings—all essential components in high-temperature industrial equipment. These formulations retain structural integrity under extreme heat (often exceeding thousands of degrees, common in metal smelting, glass production and ceramic firing), forming protective barriers that shield furnaces, reactors and kilns from direct heat damage, chemical corrosion (from molten metals or corrosive gases) and mechanical wear. Kaolin powder’s thermal shock resistance is a standout trait that sets it apart from many other fillers: it prevents cracking or spalling from sudden temperature fluctuations—such as when cold raw materials are added to hot furnaces, or when equipment cools down rapidly after hours of high-temperature operation—common scenarios in steelmaking, glass manufacturing and cement production. Its fine particles fill tiny gaps between coarser refractory materials, creating dense, homogeneous structure that improves density and mechanical strength of final products. This not only extends service life of refractory linings (reducing the frequency of costly replacements) but also reduces maintenance downtime and operational costs for industrial plants, ensuring continuous production.

Plastic and polymer industry uses kaolin powder as cost-effective reinforcement additive that upgrades material performance without sacrificing processability—a key balance for manufacturers. When added to polypropylene, polyethylene, polyvinyl chloride and other common polymers, it enhances rigidity to support structural applications (like plastic beams, automotive frames or construction brackets), improves heat resistance to suit high-temperature environments (such as under-hood automotive parts, which are exposed to engine heat, or industrial plastic components used near machinery) and boosts dimensional stability to prevent warping or shrinking after molding—critical for precision components like electronic device housings, where tight tolerances are essential. Surface-modified kaolin powder—treated with coupling agents—disperses evenly in polymer matrices, avoiding clumping and forming strong chemical bonds between mineral particles and polymer chains. This bonding increases tensile strength (resistance to stretching or tearing) and impact resistance (ability to withstand bumps, drops or mechanical stress), making plastics more durable in demanding applications. This enables production of lighter, more durable plastic products—such as automotive interior panels (which need to resist wear and temperature changes), smartphone casings (which require rigidity and impact resistance) and construction pipe fittings (which must withstand pressure and environmental exposure)—that withstand daily wear and tear. Importantly, it maintains polymer’s ability to be extruded, injected or blow-molded at standard processing conditions, ensuring manufacturers can use existing equipment without costly modifications or process adjustments.

Composite materials industry leverages kaolin powder to balance performance and cost—a persistent challenge in manufacturing high-quality, market-competitive composites. In fiber-reinforced composites (such as glass fiber, carbon fiber or aramid fiber composites), it acts as functional filler that enhances key mechanical properties—rigidity, tensile strength, wear resistance and dimensional stability—while reducing overall weight of final products. This weight reduction is critical for applications like consumer goods (where portability matters), industrial machinery parts (where lighter weight improves energy efficiency) or automotive components (where reduced weight boosts fuel economy). Kaolin powder replaces part of expensive synthetic fibers (like carbon fiber, which is costly to produce) in composite formulations, significantly lowering production costs without compromising structural integrity or performance. Its plate-like particles align parallel to composite matrices and fibers during processing, creating layered structure that improves load-bearing capacity by distributing stress evenly across the material and preventing localized damage (such as fiber breakage or matrix cracking). This makes composites suitable for wide range of uses, including industrial gear components (which need wear resistance), sports equipment (like bicycle frames or tennis rackets, which require strength and light weight) and construction reinforcements (like composite rebar, which replaces steel in corrosive environments). Its compatibility with various resins (epoxy, polyester, vinyl ester and polyurethane) ensures seamless integration into different composite formulations, adapting to diverse industry needs—from high-strength aerospace components (excluding aviation industry itself) to durable consumer products.

Electronic packaging auxiliaries sector benefits from kaolin powder’s unique combination of electrical insulating properties, chemical stability and processability—traits that are non-negotiable for protecting sensitive electronic components. It is used in encapsulation materials (like epoxy encapsulants, silicone resins or potting compounds) to enhance electrical insulation, creating reliable protective barrier that shields sensitive electronic components (such as microchips, circuit boards, sensors or capacitors) from short circuits, electrical interference (EMI/RFI) and static discharge—all of which can damage components or degrade performance. Kaolin powder improves viscosity and flowability of encapsulants: it thickens materials just enough to prevent runoff during application, while maintaining low enough viscosity to ensure material flows into tiny gaps, crevices and pinholes of electronic components during manufacturing (via casting or dispensing), providing complete, uniform coverage and protection. Its thermal stability helps dissipate heat generated by electronic devices during operation—acting as passive heat sink that draws heat away from components—preventing overheating that can degrade performance, shorten service life or cause premature failure. Chemical inertness is critical here: it ensures compatibility with other packaging materials (like plastics, metals or ceramics used in device casings) and avoids unwanted reactions (such as outgassing or chemical breakdown) that could release harmful substances, contaminate components or degrade overall package performance. This makes it valuable in packaging for consumer electronics (smartphones, laptops, televisions), industrial control systems (PLCs, sensors) and automotive electronics (engine control units, infotainment systems)—all applications where reliability and durability are paramount.

×

×