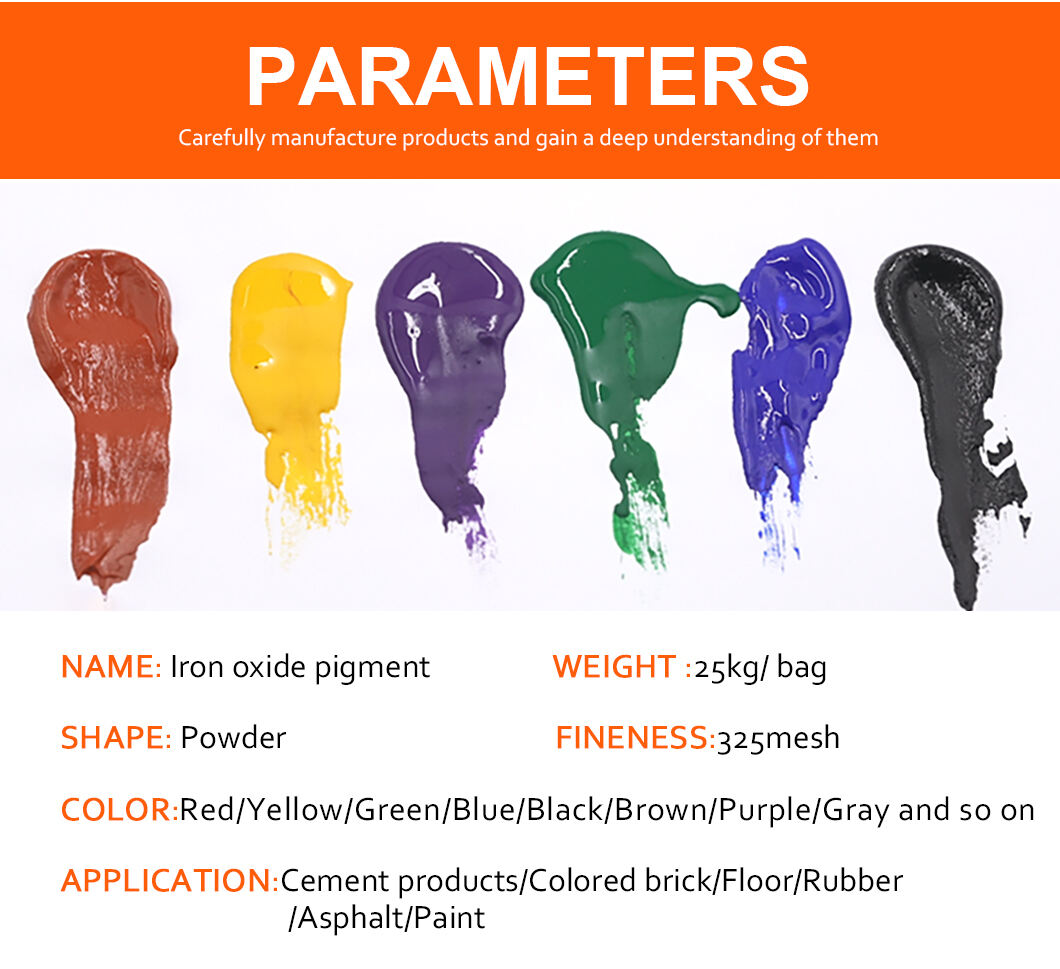

Iron oxide pigments stand as inorganic colorants derived from iron-based compounds, covering spectrum of hues from fiery reds and golden yellows to chocolate browns and jet blacks. These pigments carry inherent robustness that distinguishes them from delicate organic counterparts—organic variants often degrade under intense sunlight or chemical exposure, while iron oxide alternatives retain structure and color. This ruggedness cements their role as cornerstone for applications demanding enduring color performance, spanning outdoor installations to industrial components. Core characteristics—color fastness, resistance to environmental wear, and compatibility with diverse substrates—weave through every use case, ensuring hues remain unaltered against blistering sunlight, heavy downpours, sudden temperature swings, or even mild chemical splashes. Unlike fleeting colorants that fade to pale shades or bleed into surrounding materials over time, these pigments lock in vibrancy, becoming reliable choice for products exposed to harsh conditions or requiring prolonged aesthetic appeal, such as outdoor billboards, industrial equipment exteriors, and decorative architectural elements.

Production of iron oxide pigments follows two primary pathways: natural extraction and synthetic synthesis. Natural variants come from iron-rich ores, which undergo rigorous purification—including crushing, grinding, and magnetic separation—to remove impurities like silica or other metal oxides and standardize color consistency. Synthetic processes, favored for precise color control and batch uniformity, involve controlled reactions of iron salts through oxidation or hydrolysis. Producers meticulously adjust reaction parameters—such as temperature, pH levels, and reagent ratios—to modify particle properties, as particle size and shape directly influence tinting power, hiding capability, and dispersion. Finer particles, often measuring mere microns, enable smooth blending into thin coatings or delicate formulations like fine art paints, while coarser particles suit opaque finishes such as industrial primers. Surface treatment steps are often added to enhance performance: silane or titanate coatings, for example, boost adhesion to plastic or resin substrates, preventing clumping and ensuring uniform color distribution across every inch of material. Strict batch testing—including color matching, dispersion analysis, and weather resistance trials—ensures each production run matches color and performance standards, avoiding inconsistencies that disrupt end-product quality for manufacturers.

Outdoor art sector relies heavily on iron oxide pigments for creating murals, sculptures, and decorative installations—works designed to withstand test of time and elements. Artists choose these pigments for their exceptional lightfastness, a trait that ensures artworks retain original colors despite years of prolonged sun exposure, unlike organic pigments that may yellow or fade within months. Murals on building exteriors, park sculptures, and public art pieces use these pigments mixed with weather-resistant binders: epoxy resins for rigid sculptures to resist impact and moisture, acrylic emulsions for murals to allow slight flexibility and breathability, forming coatings that resist cracking, peeling, and discoloration. Pigments blend seamlessly with acrylics, oils, and epoxy resins, allowing artists to achieve desired textures—from smooth, glossy finishes to rough, matte surfaces—and rich color depth that adds dimension to their work. Even in extreme climates, these pigments perform reliably: in coastal regions, they withstand salt spray that corrodes other materials; in humid areas, they repel moisture to prevent mold growth on art surfaces; in arid zones, they resist UV degradation from intense sunlight. This versatility preserves artistic integrity for years without requiring frequent touch-ups, reducing maintenance efforts for art custodians.

Textile dyeing industry incorporates iron oxide pigments for coloring fabrics used in outdoor gear, workwear, and decorative textiles—products that demand both aesthetic appeal and long-term durability. Pigments bond tightly to fiber surfaces via chemical adsorption, creating colorfast finishes that resist washing, rubbing, and exposure to harsh detergents, fabric softeners, or even bleach. Cotton, polyester, and blended fabrics (such as cotton-polyester mixes) receive pigment treatments to achieve hues that stay vibrant through repeated laundering and heavy use—critical for items like outdoor tent fabrics, work uniforms, patio cushions, and awnings. Dye formulators value how these pigments integrate with both water-based and solvent-based dye systems: in water-based dyes, they disperse evenly without forming clumps; in solvent-based dyes, they maintain stability without reacting with solvents. This compatibility ensures uniform coloring across entire fabric batches, avoiding patchy or streaky results, while preserving fabric breathability and texture—outdoor gear remains lightweight and breathable, workwear stays comfortable against skin. Even after dozens of washes, fabrics colored with these pigments retain brightness, far outperforming those dyed with less durable colorants.

Industrial corrosion protection sector uses iron oxide pigments to create protective coatings for metal surfaces, a critical need for extending lifespan of industrial equipment and infrastructure. These pigments do more than add color—they form physical and chemical barrier against rust, chemical erosion, and physical abrasion. Physical barrier blocks moisture, oxygen, and corrosive agents from reaching metal substrate; chemical interaction with metal surfaces forms thin passivation layer that further inhibits oxidation. Pipelines in oil and gas industry, storage tanks for chemicals, machinery in manufacturing plants, and even offshore platform components receive coatings infused with these pigments, combining color coding (for safety and identification of pipe contents or equipment function) with robust defensive properties. Pigments blend with anti-corrosive resins (such as epoxy, polyurethane, or alkyd resins) to enhance adhesion and barrier performance, ensuring coatings adhere firmly to metal even in high-humidity, chemical-rich, or salt-laden environments. Such coatings eliminate need for frequent re-coating, reducing maintenance costs, minimizing equipment downtime, and preventing costly damage from corrosion—critical for industries where operational continuity is essential.

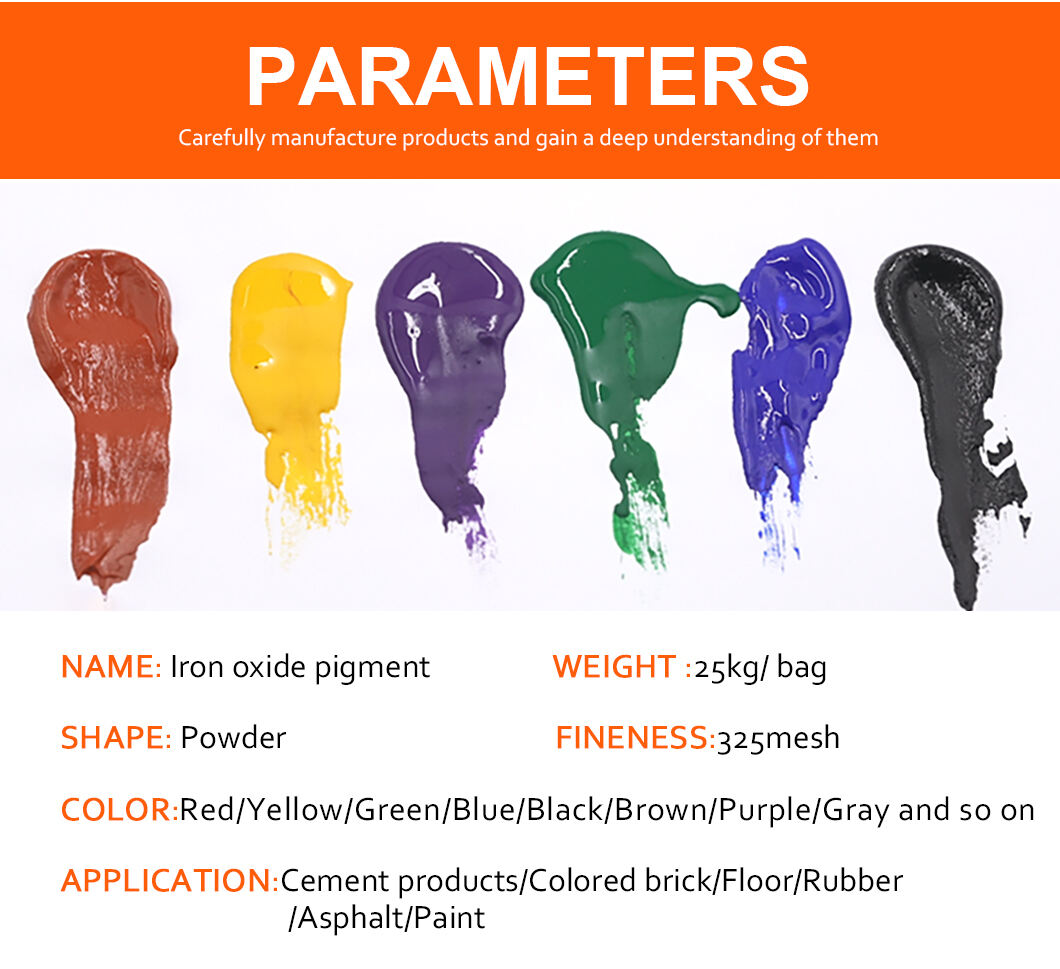

Key traits driving widespread adoption of iron oxide pigments include strong tinting power, excellent hiding capability, and consistent performance across diverse conditions. Tinting power means small amounts of pigment achieve intense, full color—far less pigment is needed compared to organic alternatives, reducing material usage and overall production costs. Hiding power allows pigments to cover imperfections (such as scratches, stains, or uneven coloring) on substrates, creating smooth, uniform finishes without need for multiple coats—saving time and labor in application processes. Chemical inertness is another standout trait: pigments do not react with solvents, acids, alkalis, or other common industrial chemicals, expanding their usability across diverse industrial settings—from acidic environments in chemical plants to alkaline conditions in construction materials. Unlike specialty colorants that are scarce, expensive, or require complex handling, these pigments are readily available in large quantities, with global supply chains supporting mass production needs without frequent disruptions.

×

×