Gummigranulater skiller seg ut som fleksible og tilpasningsdyktige materialer som skaper bro mellom utnyttelse av gummiavfall og praktiske industrielle anvendelser. Hovedsakelig produsert fra resirkulert gummi, særlig kasserte dekk, arver gummigranulater gummiens iboende egenskaper som elastisitet, slitasjemotstand og lydisolasjon, samtidig som de har egenskaper som små partikkelstørrelser og enkel blanding med andre materialer. I tillegg til kasserte dekk kan gummigranulater også produseres fra resirkulerte gummitetninger, slanger og annet gummiavfall, noe som utvider råvarekilden og forbedrer forsyningsstabiliteten. Produksjon av gummigranulater innebærer systematiske prosesser som rensing, knusing, siktning og renseprosesser: rensing fjerner søl, oljeflekker og annet tilhengende avfall fra det resirkulerte gummit; knusing bryter ned gummit i små fragmenter; siktning skiller partikler etter størrelse ved hjelp av flerlagssikter; renseprosessen fjerner ytterligere rester av urenheter for å forbedre produktets renhet. Disse prosessene fjerner ikke bare urenheter og justerer partikkelstørrelse for å oppfylle ulike brukskrav, men sikrer også konsekvent ytelse hos gummigranulatene. En slik produksjonsmåte realiserer ikke bare resirkulering av gummiavfall, men gir også kostnadseffektive materialer til flere industrier, og bidrar til utviklingen av relaterte industriled, inkludert innsamling, behandling og videre anvendelse av avfall.

Bygging av bylandskap har blitt et viktig anvendelsesområde for gummi granulater, hvor deres unike egenskaper gir nye muligheter for urban grønnutvikling og ombygging av offentlige rom. Ved anlegg av fotveier og parkstier blandes gummi granulater med sement eller harpiks for å danne skridsikre og støtdempende dekkeflater, som er behagelige å gå på og kan redusere støy fra fotgjengere, og dermed skape mer rolige og behagelige gangmiljøer i byene. Fargede gummi granulater, med rike og klare nyanser fra myke pasteller til levende neonguler, brukes mye i design av bylandskapskisser, barnelekeplasser og fellesskapsgrøne soner. Disse fargede gummi granulatene forbedrer ikke bare den visuelle estetikken i byrommene og gjør offentlige områder mer livlige og tiltrekkende, men har også utmerket værbestandighet – de tåler solfading, nedbørskjemi og frostskader, og beholder stabil farge og ytelse selv ved langvarig utendørs eksponering. Gummigranulatdekker viser også stor tilpasningsevne til ulike terrengforhold, og lar seg enkelt bygge på skråninger eller uregelmessig underlag uten kompleks grunnarbeid, noe som forenkler byggeprosessene i bylandskapsprosjekter og reduserer totale byggekostnader.

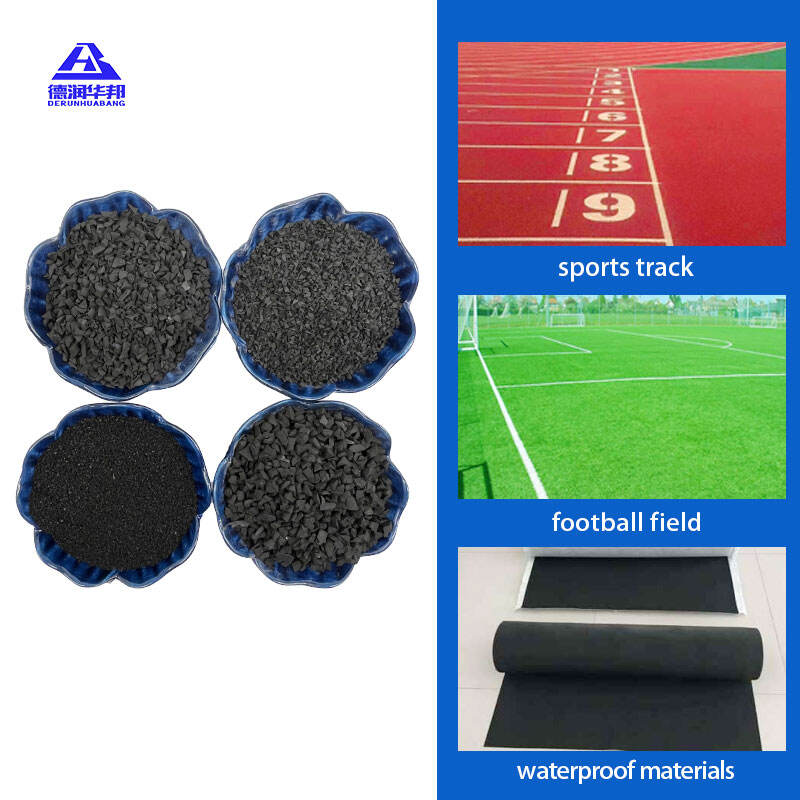

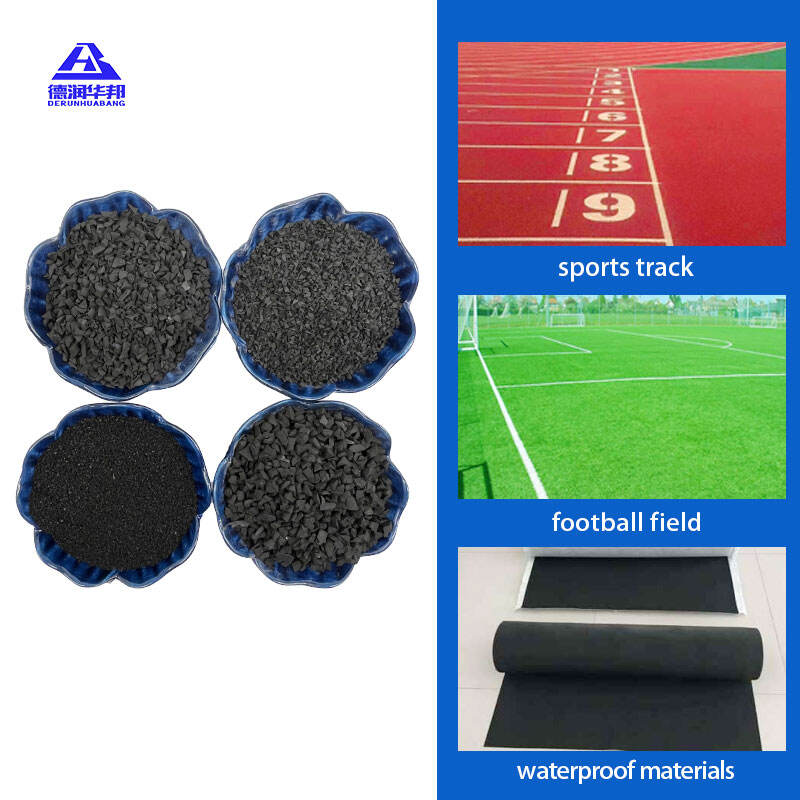

Forbedring av idrettsanlegg er i stor grad avhengig av gummi granulat, som har blitt grunnleggende materialer for oppgradering og bygging av idrettsanlegg. Ved konstruksjon av utendørs og innendørs idrettsbaner brukes gummi granulat som nøkkelkomponenter i overflatelag og fyllmaterialer, og påvirker direkte sikkerheten og idrettsopplevelsen i anleggene. For eksempel, ved bygging av basketball- og badmintonbaner blandes gummi granulat med polyurethan-materialer for å danne elastiske overflatelag som effektivt kan redusere påvirkning på utstyr under idrett, redusere friksjon mellom utstyr og gulv, samt forbedre idrettsopplevelsen ved å gi passende sprett og grep. På kunstgressfotballbaner fungerer gummi granulat som fyllstoff for å feste gressfibrene, hindre at fibrene legger seg flatt pga. hyppig tråkk, bevare flat overflate og gi en passende dempende kraft for å beskytte utøvere mot støt fra hardt underlag. EPDM-gummi granulat, med overlegen aldringsbestandighet, strekkfasthet og ozonbestandighet, brukes mye i profesjonelle idrettsanlegg som krever høy ytelse og lang levetid, ettersom de tåler intensivt bruk og harde miljøforhold uten vesentlig ytelsesnedgang. Også ved modernisering av eldre idrettsanlegg brukes ofte gummi granulat til reparasjon av slitne overflater – ved å legge på nytt lag eller blande med reparasjonsmaterialer kan slitne områder gjenopprettes til sin opprinnelige ytelse, og dermed forlenge levetiden til anlegget uten omfattende rekonstruksjon eller utskifting av hele overflaten.

Kontinuerlig optimalisering av produksjonsteknologi for gummi granulat bidrar til forbedring av produktkvalitet og utvidelse av bruksområder. Den tradisjonelle fysiske knusingsteknologien gradvis oppgraderes med tillegget av intelligente siktanlegg, som kan kontrollere partikkelfordelingen av gummi granulat mer nøyaktig, og sikre at hver parti oppfyller spesifikke brukskrav samt redusere ytelsesforskjeller mellom partier. Nye teknologier, som kuldeknusing, reduserer ytterligere skader på gummiens molekylstruktur under produksjon – ved å kjøle gummi til et sprøtt tilstand ved lave temperaturer, kan knusing oppnås med minimal varmeutvikling, og dermed sikres det at gummi granulatet beholder fremragende fysiske egenskaper som elastisitet og slagstyrke. Overflatemodifiseringsteknologi for gummi granulat, gjennom kjemisk behandling som grafting eller belegging, øker kompatibiliteten og limstyrken mellom gummi granulat og andre materialer som bitumen, harpiks og sement, noe som gjør dem mer egnet for krevende anvendelser som krever sterk adhesjon og strukturell stabilitet. Disse teknologiske fremskrittene fremmer ikke bare standardisering og finjustering av produksjonen av gummi granulat, men legger også et solidt grunnlag for deres bredere anvendelse i høyteknologiske og spesialiserte felt.

Verdensmarkedet for gummi granulat viser tydelige regionale utviklingstrekk, der ulike regioner fokuserer på forskjellige anvendelsesområder og har distinkte markedsbehov. I Nord-Amerika og Europa brukes gummi granulat hovedsakelig i high-end sportsanlegg og bylandskapsprosjekter, med høye krav til produktkvalitet, miljøprestasjoner og sikkerhetsstandarder – produktene må bestå strenge miljøtester og kvalitetsertifiseringer for å komme inn på lokale markeder. I Stillehavsregionen vokser etterspørselen etter gummi granulat raskt, drevet av hurtig urbanisering, økende investeringer i sportsinfrastruktur og kontinuerlig utvidelse av byens offentlige rom. Anvendelsesområdene her utvides stadig fra tradisjonell bygging til nye områder som innendørs dekorasjon, industriell støyreduksjon og kommersielle fotgjengerstrøk. Konkurransen i gummi granulat-industrien speiles hovedsakelig i produksjonsteknologi, produktkvalitet og pris: bedrifter med avansert teknologi kan produsere høytytende gummi granulat for å dominere toppsegmentet, mens de med kostnadsfordeler er mer konkurransedyktige i massemarkedet. Denne konkurransen fører til at bedrifter øker sine investeringer i forskning og utvikling, optimaliserer produksjonsprosesser og forbedrer sin kjernekompetanse for å vinne større markedsandel.

Anvendelsen av gummi granulater står også overfor noen praktiske problemer som må løses for å fremme en sunnere utvikling. Et av disse er kontroll av lukt under produksjon og bruk – noe gummi granulater kan utløse svak lukt på grunn av rester av tilsetningsstoffer eller ufullstendig bearbeiding, noe som påvirker brukeropplevelsen i lukkede eller delvis lukkede rom. Dette krever at bedrifter optimaliserer produksjonsprosesser, benytter miljøvennlige tilsetningsstoffer og inkluderer avluktningssteg for å redusere utslipp av flyktige stoffer. Et annet problem er forbedring av holdbarheten til produkter med gummi granulater i ekstreme miljøer, som høy temperatur, lav temperatur og høy fuktighet: I høye temperaturer kan gummi granulatene bli myke og miste elastisiteten; i lave temperaturer kan de bli sprø og sprekke; og høy fuktighet kan føre til akselerert aldring. Å løse disse problemene krever grundig forskning på matrialeformler og modifiseringsteknologi, for eksempel ved å tilsette anti-aldrende midler eller bruke sammensatte materialer for å forbedre tilpasningsevnen til ulike miljøer.