Sepiolite Fiber is natural mineral formed through long term and complex geological evolution, mainly originating from shallow marine, lacustrine or lagoonal sedimentary environments where magnesium rich minerals (such as serpentine and olivine) interact with alkaline water and carbon dioxide over thousands of years. This slow chemical reaction promotes crystallization of magnesium silicate, gradually forming slender, thread like crystals that naturally aggregate into flexible fibrous bundles. Most distinctive feature of Sepiolite Fiber is its internal porous structure, which consists of countless tiny parallel channels running along fiber length and interconnected micro voids between crystal layers. This unique structure is stably formed during mineralization and remains intact through gentle mining and processing methods—such as light pressure crushing and air classification—that avoid damaging delicate fiber bundles, laying solid foundation for its diverse application properties in multiple fields.

Core properties of Sepiolite Fiber include excellent sound insulation, strong adsorption capacity and good dispersion stabilization, which are all closely related to its inherent structure. Porous structure can effectively trap sound waves of different frequencies; when sound waves enter voids, they collide with air molecules and pore walls, converting sound energy into weak heat energy through friction and viscous resistance, thereby achieving obvious sound insulation effect. Adsorption capacity comes from extremely large specific surface area provided by porous structure—each gram of Sepiolite Fiber has surface area enough to cover large area, enabling it to effectively capture liquids, gases and solid particles. Surface hydroxyl groups on Sepiolite Fiber further enhance adsorption by forming hydrogen bonds or chemical complexes with target molecules. Dispersion stabilization means Sepiolite Fiber can be evenly distributed in water based, oil based or solid media without agglomeration; its fibrous morphology helps it form loose network to maintain stability of system structure. These properties complement and promote each other, making Sepiolite Fiber suitable for multiple industrial and civilian fields.

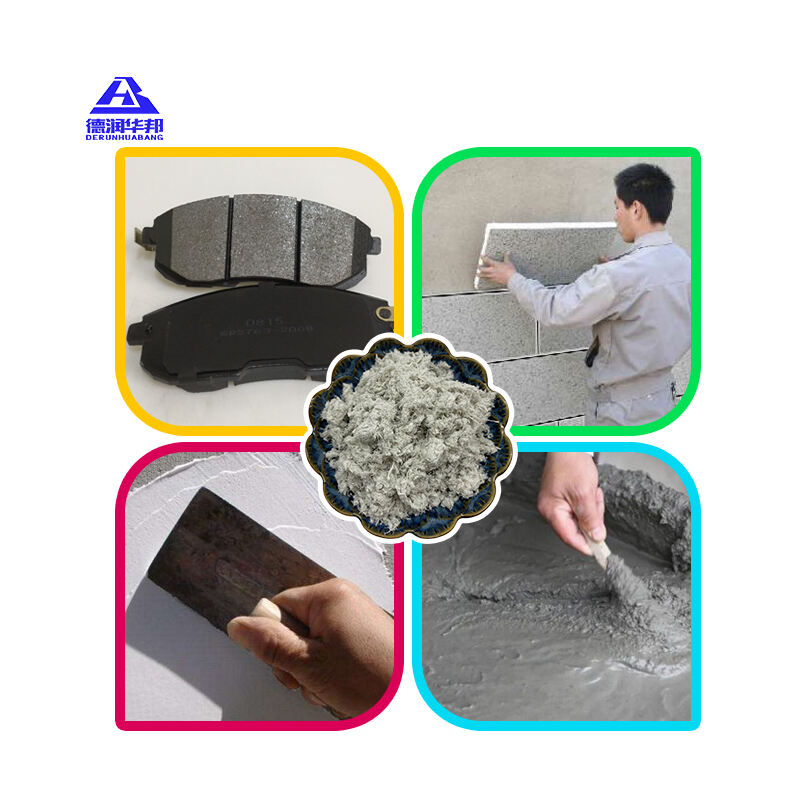

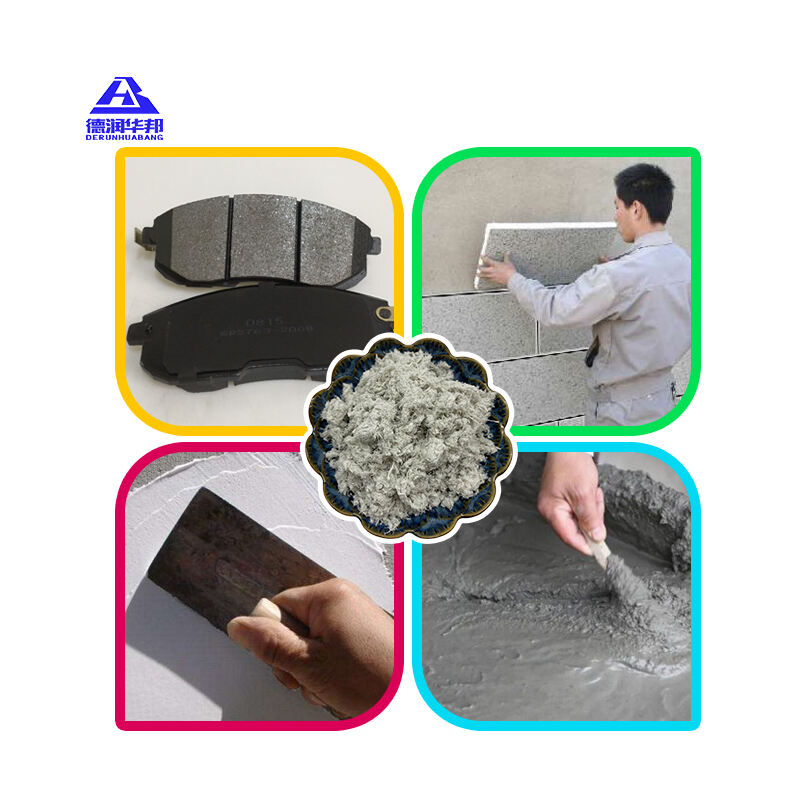

Soundproof materials industry is important and mature application field of Sepiolite Fiber. When added to soundproof panels, household soundproof carpets, building wall insulation materials and vehicle interior linings, Sepiolite Fiber significantly improves sound insulation performance of end products. Its slender fibrous structure interweaves tightly with base materials (such as polyurethane foam, gypsum and polyester fiber) to form dense and uniform sound insulation layer, which blocks direct transmission of sound waves; meanwhile, porous structure further absorbs residual sound waves that pass through surface layer, especially medium and low frequency noise that is difficult to handle. Compared with traditional soundproof materials like glass wool or rock wool, those containing Sepiolite Fiber have lighter weight while ensuring equivalent or better sound insulation effect, which is more conducive to on site installation and reduces load of buildings or vehicles. In residential buildings, such soundproof materials can reduce noise transmission between floors and adjacent rooms, creating quiet living environment; in vehicles (including cars, trains and airplanes), they can effectively reduce engine vibration noise, road friction noise and aerodynamic noise, greatly improving riding comfort.

Oilfield drilling fluids sector widely and maturely uses Sepiolite Fiber for its excellent stabilization and targeted adsorption properties. Drilling fluids (also called drilling mud) play crucial roles in cooling drill bits, carrying rock cuttings to surface, lubricating drill strings and stabilizing well walls during oil and gas drilling. Adding appropriate proportion of Sepiolite Fiber to water based or oil based drilling fluids can significantly enhance viscosity and shear force of fluids, forming stable suspension system that prevents rock cuttings from settling at bottom of well. Porous structure of Sepiolite Fiber can specifically adsorb harmful colloidal particles and heavy metal ions in drilling fluids, purifying fluid system; its fibrous surface also reduces direct friction between drill strings and well walls, lowering wear of drill tools. More importantly, Sepiolite Fiber has good temperature resistance—it can maintain stable structure and performance in high temperature deep well environments where temperature exceeds hundreds of degrees. Using Sepiolite Fiber in drilling fluids not only improves drilling speed and efficiency, but also effectively reduces occurrence of well collapse, stuck drill and other dangerous accidents, ensuring safety of drilling operations.

Pet cleaning products field is emerging and fast growing application area where Sepiolite Fiber shows unique and irreplaceable advantages. It is widely used as main functional component of pet litter (especially cat litter), pet fur cleaning powders and cage decontamination agents due to its super strong water absorption and efficient odor adsorption. Porous structure of Sepiolite Fiber has extremely strong capillary action, which can quickly absorb moisture in pet excrement, forming solid clumps that are easy to clean and remove; surface functional groups (such as hydroxyl and siloxane groups) can strongly adsorb ammonia, hydrogen sulfide and other odorous substances produced by pet excrement, keeping pet living environment clean and odorless for long time. Compared with traditional pet cleaning materials like bentonite cat litter or paper scraps, Sepiolite Fiber has better water absorption capacity (absorbing several times its own weight in water) and longer service life—each replacement cycle can be extended by days.

Processing process of Sepiolite Fiber is simple, efficient and environmentally friendly, with core principle of preserving its natural fibrous structure and porous properties. After mining raw ore from mineral deposits, first step is natural air drying or low temperature drying to remove surface moisture (avoiding high temperature that may damage pore structure), then raw ore is crushed into small particles through roller crusher (with gentle pressure to prevent fiber breakage). Next, key process of fiber separation is carried out through air classification equipment—adjusting air flow speed to make lightweight, slender Sepiolite Fiber be carried by air flow and separated from heavy impurities such as sand, stone and clay. For different application fields, targeted modification can be carried out without destroying main properties: for pet cleaning products, surface activation treatment is adopted to enhance water absorption and odor adsorption; for soundproof materials, it is mixed with small amount of environmentally friendly binders to improve cohesion with base materials; for drilling fluids, it is subjected to anti caking treatment to ensure dispersion in fluids. All these processing steps have low energy consumption, no chemical additives that produce harmful by products, and fully conform to modern industrial production requirements of energy saving and environmental protection.

×

×