Paglalarawan

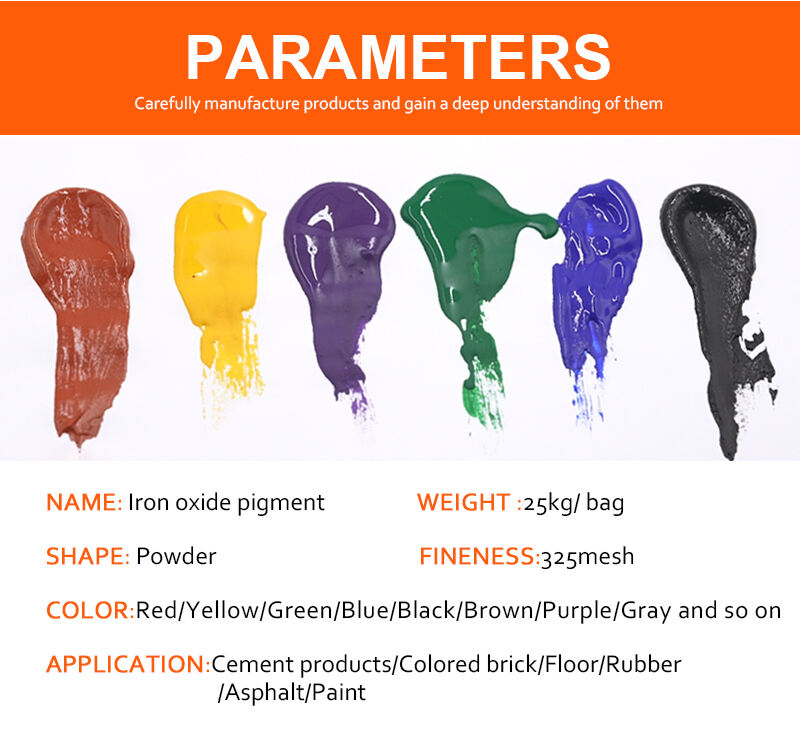

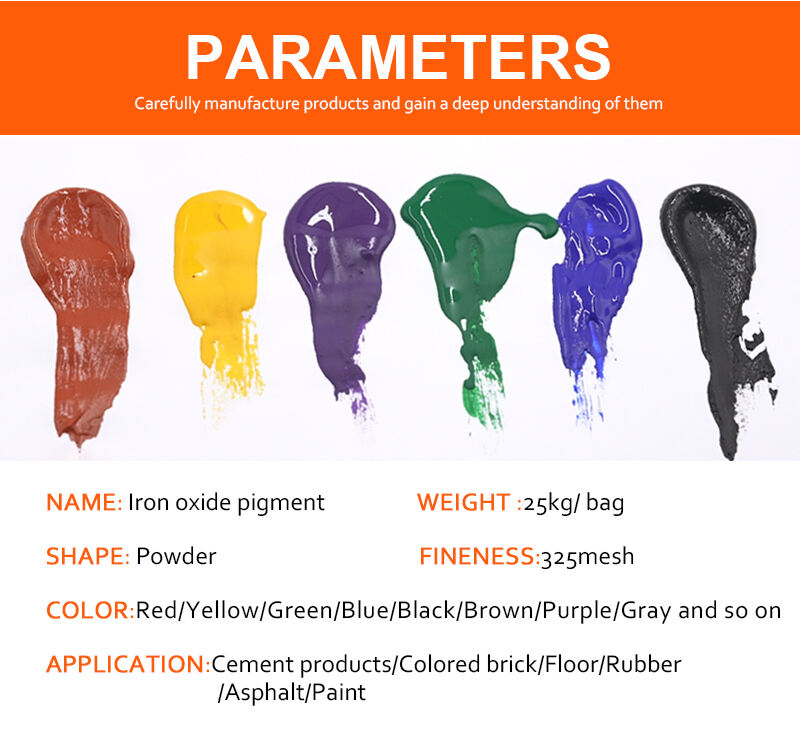

Ang mga pigmentong iron oxide na mataas ang kalidad ay naging mahahalagang materyales na ginagamit sa iba't ibang industriya tulad ng konstruksyon, pintura, plastik, at ceramic dahil sa kanilang mahusay na istabilidad ng kulay, matibay na resistensya sa panahon, at maraming aplikasyon. Ang mga pigmentong ito, na makukuha sa iba't ibang kulay tulad ng pula, dilaw, itim, at kayumanggi, ay ginawa sa pamamagitan ng mga advanced na proseso na nagsisiguro ng pare-parehong kalidad, kaya't ito ay isang maaasahang pagpipilian para sa mga tagagawa at supplier na naghahanap na mapahusay ang pagganap at aesthetic appeal ng kanilang produkto.

Sa industriya ng konstruksyon, ang iron oxide pigments ay gumaganap ng mahalagang papel sa pagdaragdag ng kulay at tibay sa iba't ibang materyales sa gusali. Ang kongkreto, na isa sa mga pinakagamit na materyales sa konstruksyon, ay kadalasang umaasa sa iron oxide pigments upang makamit ang ninanais na mga kulay--mula sa mainit na pula para sa dekorasyong kongkreto na daanan hanggang sa maitim na kayumanggi para sa mga panlabas na pader. Hindi tulad ng ibang mga pigment na maaaring lumabo o sumira sa paglipas ng panahon, ang iron oxide pigments ay nagpapanatili ng kanilang kulay kahit kapag nalantad sa matinding lagay ng panahon, kabilang ang matinding sikat ng araw, malakas na ulan, at sobrang temperatura. Ang resistensya nito sa panahon ay lalong mahalaga para sa mga proyekto sa konstruksyon sa labas, dahil nagsisiguro ito na mananatiling kaakit-akit ang mga gusali at istruktura sa loob ng maraming dekada. Halimbawa, ang mga dekorasyong kalsada na may kulay na pula ng iron oxide pigment ay nananatiling sariwa kahit pagkalipas ng ilang taon ng pagkalantad sa UV rays, habang ang mga kongkretong retaining wall na may kulay na dilaw ng iron oxide pigment ay hindi nawawalan ng kanilang ningning dahil sa ulan o yelo. Bukod pa rito, ang iron oxide pigments ay hindi nakakalason at kemikal na matatag, na nagpapahintulot sa kanila na gamitin nang ligtas sa mga materyales sa konstruksyon na nakikipag-ugnay sa kapaligiran o sa mga tao, tulad ng sahig ng tirahan o sa mga daanan sa pampublikong parke.

Ang industriya ng mga patong ay isa pang pangunahing gumagamit ng mga pigmentong iron oxide na may mataas na kalidad, kung saan ginagamit ang mga ito sa produksyon ng mga industrial coating, architectural coating, at automotive coating. Sa mga industrial coating, ang mga pigmentong ito ay hindi lamang nagbibigay ng kulay kundi pati na rin ng mas mahusay na proteksyon laban sa korosyon at pagsusuot. Halimbawa, ang mga istrukturang metal tulad ng mga steel bridge o kagamitang pang-industriya ay karaniwang nababalot ng mga pinturang naglalaman ng pigmentong iron oxide black, na bumubuo ng isang protektibong layer na nagpapigil sa kalawang at nagpapahaba sa buhay ng metal. Sa architectural coatings, hinahangaan ang mga pigmentong iron oxide dahil sa kanilang kakayahang lumikha ng makulay, matagalang kulay para sa mga pader sa loob at labas. Ang mga may-ari ng bahay at komersyal na ari-arian ay madalas pumipili ng mga pintura na may iron oxide red o brown pigments para sa mga panlabas na pader, dahil ang mga kulay na ito ay nakakatag ng pagkaputik at nagpapanatili ng sariwang anyo sa loob ng maraming taon. Ang automotive coatings ay nakikinabang din sa mga pigmentong iron oxide, lalo na sa mga undercoating at mga formula ng primer, kung saan ang kanilang mataas na hiding power at mga katangian ng pagkakadikit ay tumutulong sa paglikha ng isang maayos, pare-parehong base para sa topcoats. Hindi tulad ng mga organic pigments na maaaring masira sa ilalim ng UV exposure, ang mga iron oxide pigments ay nagpapanatili ng kanilang kulay at protektibong katangian, na nagsisiguro na manatiling matibay at kaakit-akit ang automotive coatings.

Ang pagmamanupaktura ng plastik ay isa pa ring industriya na umaasa nang malaki sa mga pigmentong iron oxide na mataas ang kalidad. Ginagamit ang mga pigmentong ito upang kulayan ang malawak na hanay ng mga produktong plastik, kabilang ang mga tubong PVC, lalagyan ng polyethylene, laruan ng polypropylene, at mga bahagi ng plastik na ABS. Isa sa mga pangunahing bentahe ng mga pigmentong iron oxide sa plastik ay ang kanilang mahusay na istabilidad sa init. Sa panahon ng proseso ng plastic extrusion o injection molding, ang mga materyales ay nalantad sa mataas na temperatura, at maraming mga pigment ay maaaring magbago ng kulay o bumulok sa ilalim ng mga kondisyong ito. Gayunpaman, ang mga pigmentong iron oxide ay kayang-kaya ang mga temperatura na umaabot sa 300°C nang hindi nawawala ang kanilang kulay o mga katangiang kemikal, na ginagawa silang angkop para sa pinakamahihirap na proseso ng pagmamanupaktura ng plastik. Bukod dito, ang mga pigmentong iron oxide ay may magandang mga katangiang pang-iyak, na nangangahulugan na maari silang pantay na haloing mabuti sa mga resin ng plastik upang makalikha ng pare-parehong kulay sa kabuuan ng produkto. Ito ay mahalaga para sa mga produktong plastik tulad ng mga tubong PVC, kung saan ang pare-parehong kulay ay nagpapahiwatig ng pare-parehong kalidad, at para sa mga laruan, kung saan ang maliwanag at pantay na mga kulay ay mahalaga para sa pagkakagusto ng mga konsyumer. Ang mga pigmentong iron oxide ay hindi rin umaagos o dumudumi sa ibang mga materyales, na nagagarantiya na ang may kulay na plastik ay hindi magpapakita ng mantsa sa mga kalapit na ibabaw o mawawala ang kanilang kulay sa paglipas ng panahon.

Ang industriya ng ceramics ay nagpapahalaga rin sa mga mataas na kalidad na iron oxide pigments dahil sa kanilang kakayahang lumikha ng makulay at matatag na kulay sa mga ceramic produkto tulad ng tiles, palayok, at sanitary wares. Sa pagmamanupaktura ng ceramic tile, ang iron oxide pigments ay idinadagdag sa glaze o katawan ng tile upang makagawa ng mga kulay mula sa lupaing kayumanggi hanggang sa makulay na pula. Ang mga pigment na ito ay nakakatagal sa mataas na temperatura ng ceramic firing (madalas na umaabot sa mahigit 1200°C) nang hindi nawawala ang kulay o nagbabago, na nagsisiguro na ang ceramic tiles ay pananatilihin ang kanilang anyo kahit pagkatapos ng paulit-ulit na paggamit at paglilinis. Halimbawa, ang mga floor tile na may kulay mula sa iron oxide yellow pigments ay nananatiling mainit ang kulay kahit sa mga mataong lugar tulad ng kusina o koridor, samantalang ang mga wall tile na may iron oxide red pigments ay hindi nawawalan ng intensity kahit ilagay sa kahalumigmigan sa mga banyo o shower. Sa paggawa ng palayok at sining na ceramics, ginagamit ng mga artista ang iron oxide pigments upang makalikha ng natatanging epekto sa kulay, dahil ang mga pigment na ito ay maaaring makireaksiyon sa ibang ceramic na materyales habang nasa proseso ng firing upang makagawa ng mga sutil na pagkakaiba sa kulay at tekstura. Bukod pa rito, ang iron oxide pigments ay hindi nakakalason, na nagpapahintulot sa kanila na gamitin nang ligtas sa mga ceramic produkto na nakakasalamuha ng pagkain, tulad ng mga pinggan, bagaman mas karaniwan silang ginagamit sa mga dekorasyong ceramics kung saan ang mga pamantayan sa kaligtasan para sa pakikipag-ugnay sa pagkain ay hindi gaanong mahigpit.

Higit sa kanilang mga aplikasyon sa mga pangunahing industriya, ang mga mataas na kalidad na iron oxide pigment ay nag-aalok ng ilang iba pang mga benepisyo na nagtatagpo sa kanila bilang paboritong pagpipilian ng mga manufacturer. Isa sa mga ganitong benepisyo ay ang kanilang cost-effectiveness. Ang iron oxide pigments ay malawakang makukuha at relatibong mura kumpara sa iba pang uri ng pigment, tulad ng organic pigments o rare earth pigments. Ito ang nagiging dahilan para maging abot-kaya ang mga ito para sa malalaking operasyon sa pagmamanupaktura, kung saan ang pagbawas sa gastos sa materyales ay isang pangunahing prayoridad. Bukod pa rito, ang iron oxide pigments ay may mataas na tinting strength, na nangangahulugan na ang maliit na dami ng pigment ay maaaring makagawa ng matibay na kulay, lalo pang binabawasan ang dami ng pigment na kailangan bawat produkto at nagpapababa sa kabuuang gastos sa produksyon.

Isa pang benepisyo ng iron oxide pigments ay ang kanilang pagiging magiliw sa kapaligiran. Karamihan sa iron oxide pigments ay galing sa natural na yero ores o ginawa sa pamamagitan ng mga proseso na nakabatay sa pagpapanatili ng kapaligiran, at ganap silang nabubulok at hindi nakakalason. Hindi tulad ng ilang synthetic pigments na maaaring maglabas ng nakakapinsalang kemikal sa kapaligiran habang ginagawa o binubura, ang iron oxide pigments ay walang panganib sa kalusugan ng tao o sa mga ekosistema. Dahil dito, ang mga ito ay isang angkop na pagpipilian para sa mga manufacturer na naghahanap upang matugunan ang mga regulasyon sa kapaligiran at bawasan ang kanilang carbon footprint. Maraming industriya, tulad ng konstruksyon at sektor ng panggawi, ay bawat taon na binibigyan ng higit na prayoridad ang mga materyales na magiliw sa kalikasan, at ang iron oxide pigments ay tugma sa uso na ito, na tumutulong sa mga manufacturer na makalikha ng higit na napapanatiling mga produkto.

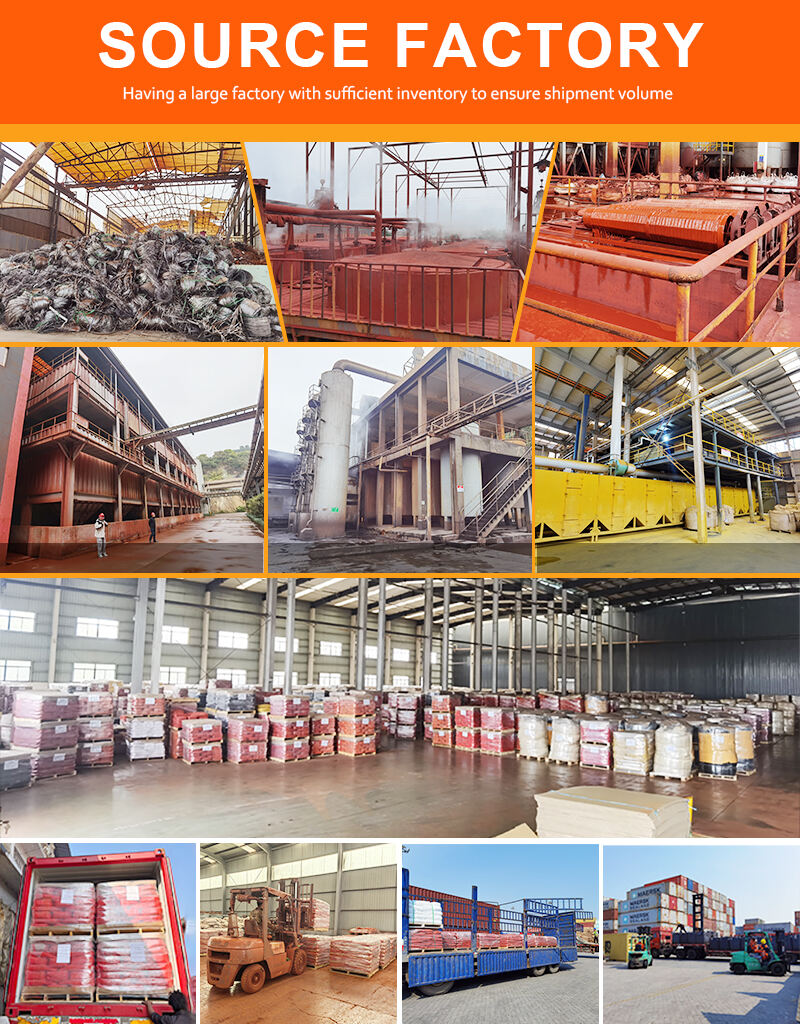

Sa aspeto ng imbakan at paghawak, ang mga pigmentong iron oxide na mataas ang kalidad ay madaling mapapamahalaan. Ito ay nasa anyong pulbos, na matatag at hindi dumudikit o sumusugpo kapag inimbak sa isang lugar na malamig at tuyo. Dahil sa mahabang shelf life nito, ang mga gumagawa ay maaaring bumili ng iron oxide pigments nang maramihan, binabawasan ang bilang ng mga order at nagpapababa sa gastos sa transportasyon. Bukod pa rito, ang iron oxide pigments ay hindi nakakaburning at hindi paputok, kaya ligtas itong transportihin at imbakin, kahit sa malalaking dami.

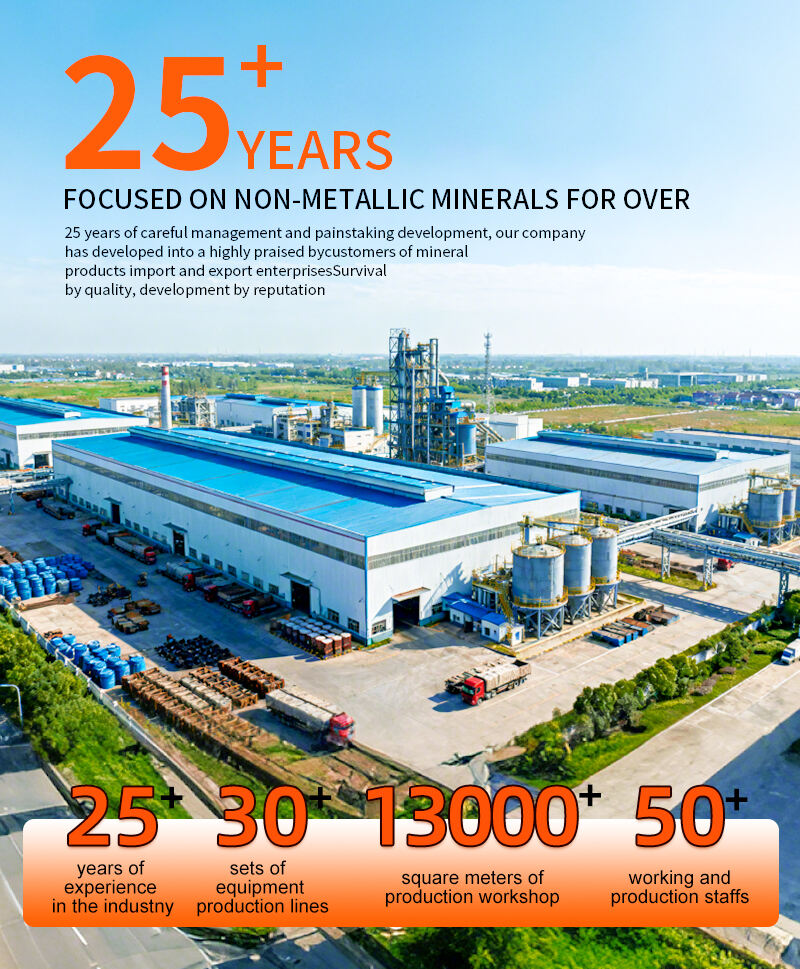

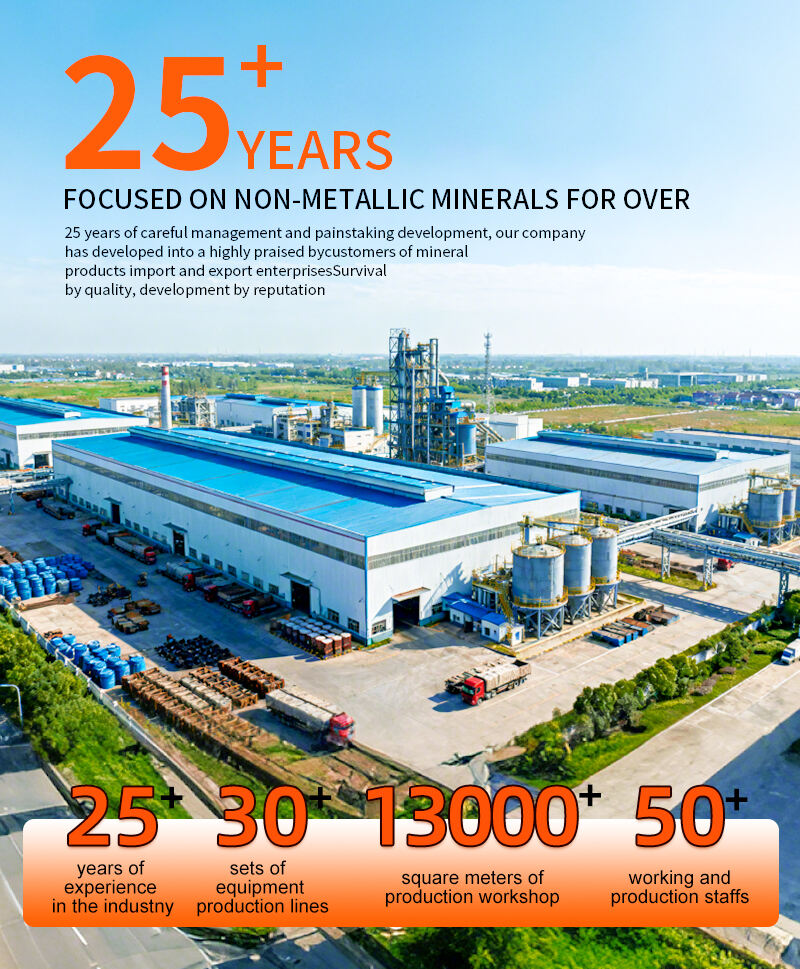

Sa konklusyon, ang mga pigmentong iron oxide na may mataas na kalidad ay mga materyales na maraming gamit, matibay, at ekonomikal na mahalaga sa industriya ng konstruksyon, pintura, plastik, at ceramic. Ang kanilang mahusay na istabilidad sa kulay, pagtutol sa panahon, pagtutol sa init, at pagiging magalang sa kalikasan ay nag-uugnay sa kanila bilang paboritong pagpipilian ng mga manufacturer na naghahanap upang mapabuti ang kalidad ng produkto, bawasan ang gastos, at matugunan ang mga layunin sa mapagkakatiwalaang pag-unlad. Kung gagamit para kulayan ang mga istrukturang konkreto, protektahan ang metal gamit ang mga pintura, dagdagan ang ningning ng mga plastik, o lumikha ng makulay na mga ceramic, ang iron oxide pigments ay nagbibigay ng pare-parehong pagganap at matagalang resulta. Para sa mga negosyo sa mga industriyang ito, ang pag-invest sa mga iron oxide pigments na may mataas na kalidad ay isang matalinong desisyon na maaaring mapabuti ang pagiging kaakit-akit ng produkto, palawigin ang buhay ng produkto, at suportahan ang pangmatagalang tagumpay ng negosyo.