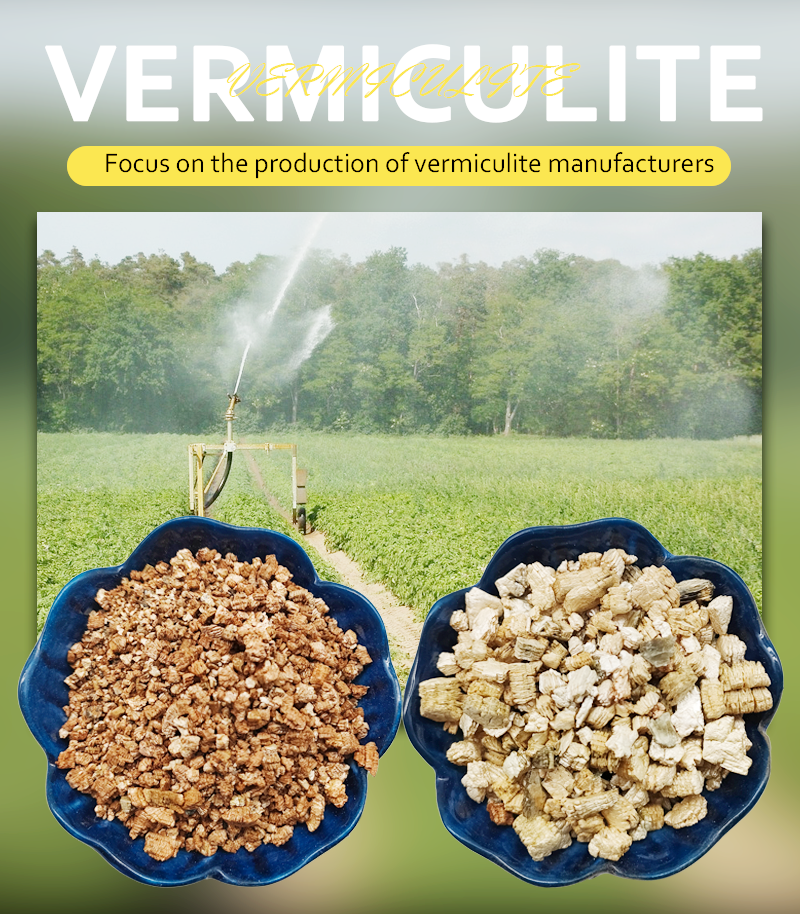

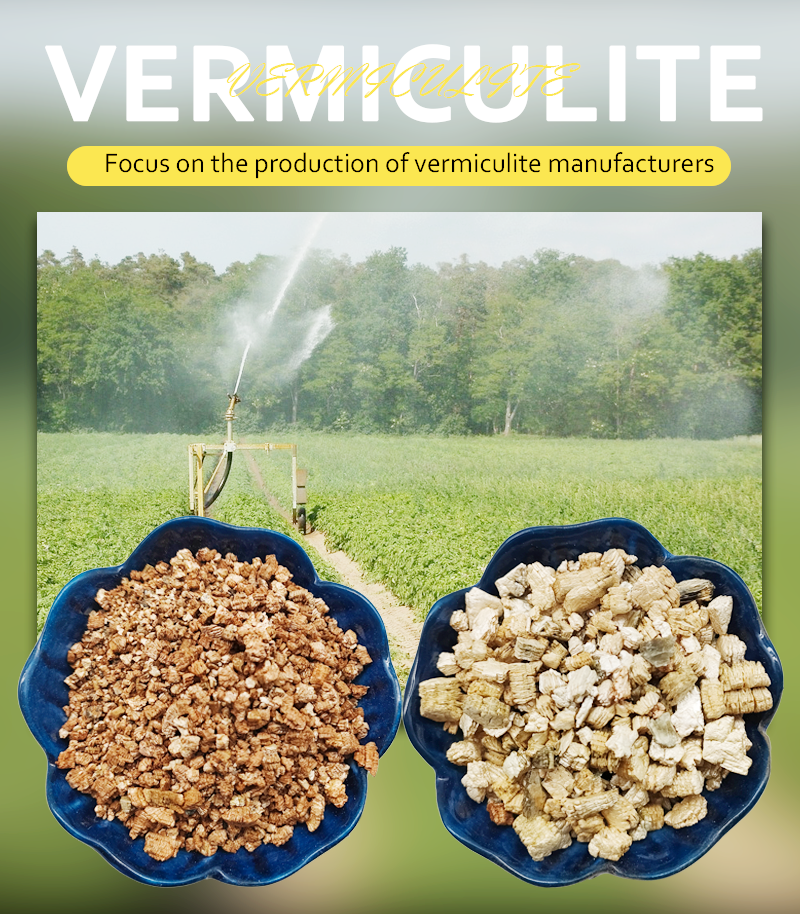

Vermiculite emerges as versatile mineral material that caters to diverse demands of Architectural Insulation, Material Engineering, and Industrial Applications. Unlike single-function mineral materials such as perlite or mica—limited by narrow performance ranges like perlite’s poor fire resistance or mica’s weak thermal insulation—Vermiculite exhibits unique combination of physical traits: lightweight, porous structure after expansion, exceptional thermal insulation that outperforms many synthetic insulators, and inherent strong fire resistance that resists combustion even under high heat. These traits collectively enhance functionality of end products across industries, from construction to packaging. Derived from natural vermiculite ore deposits with layered crystalline structures—formed via hydrothermal alteration of biotite or phlogopite—Vermiculite undergoes physical processing without toxic chemicals or synthetic modifiers, aligning with modern trends focused on durable, low-maintenance, and application-flexible materials. Serving as core component in Fire Resistance materials, Sound Absorption products, and Packaging Cushion, Vermiculite transcends ordinary mineral status to become multi-purpose solution blending structural protection against heat and fire, functional efficiency in energy and noise reduction, and cost-effectiveness from abundant raw materials and simple processing.

Resource foundation of Vermiculite combines natural abundance and regional trait diversity, with ore properties precisely tailored to specific application needs. Natural vermiculite ore forms in distinct geological settings worldwide—primarily in association with igneous and metamorphic rocks—each yielding material with unique characteristics that match industrial demands. South African vermiculite deposits, among largest globally, produce ore with high expansion ratio (expanding up to multiple times its original volume when heated) and superior thermal stability, making it ideal for Thermal Insulation in industrial kilns and Refractory Material for high-temperature equipment. American vermiculite ore, concentrated in Montana and South Carolina, yields layers with exceptional flexibility and tensile strength, perfect for Packaging Cushion that needs to repeatedly absorb impact and Sound Absorption mats that require layered structure to trap sound waves. Chinese vermiculite deposits, spread across Xinjiang and Hebei, offer high-purity ore with minimal impurity content, suited for Construction Material like lightweight concrete that requires structural integrity without compromising insulation. Mining of vermiculite ore adheres to selective extraction protocols: surface mining is prioritized to avoid deep geological disruption that could damage ore’s layered structure, and ore sorting relies on physical screening and air classification to separate vermiculite layers from associated minerals like mica, quartz, and feldspar. This careful sorting preserves inherent layered structure—critical for subsequent expansion and performance of end products.

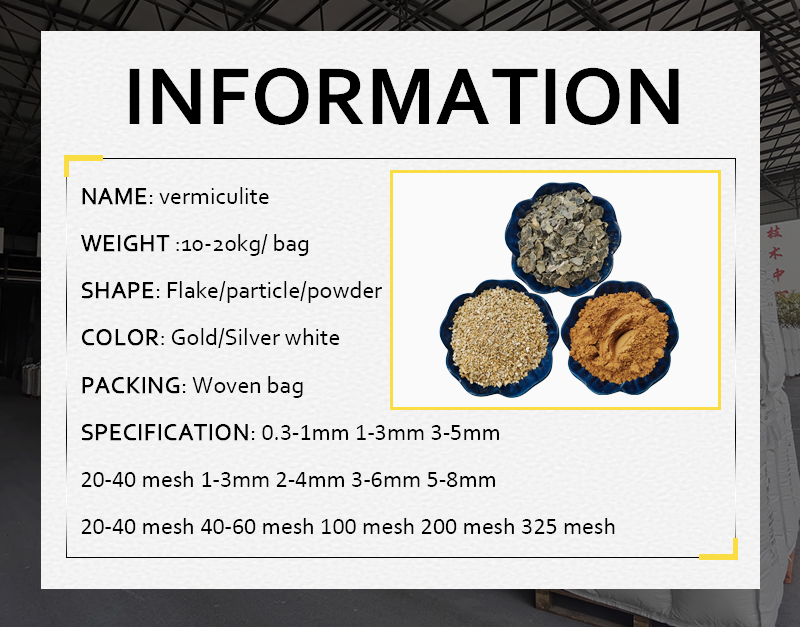

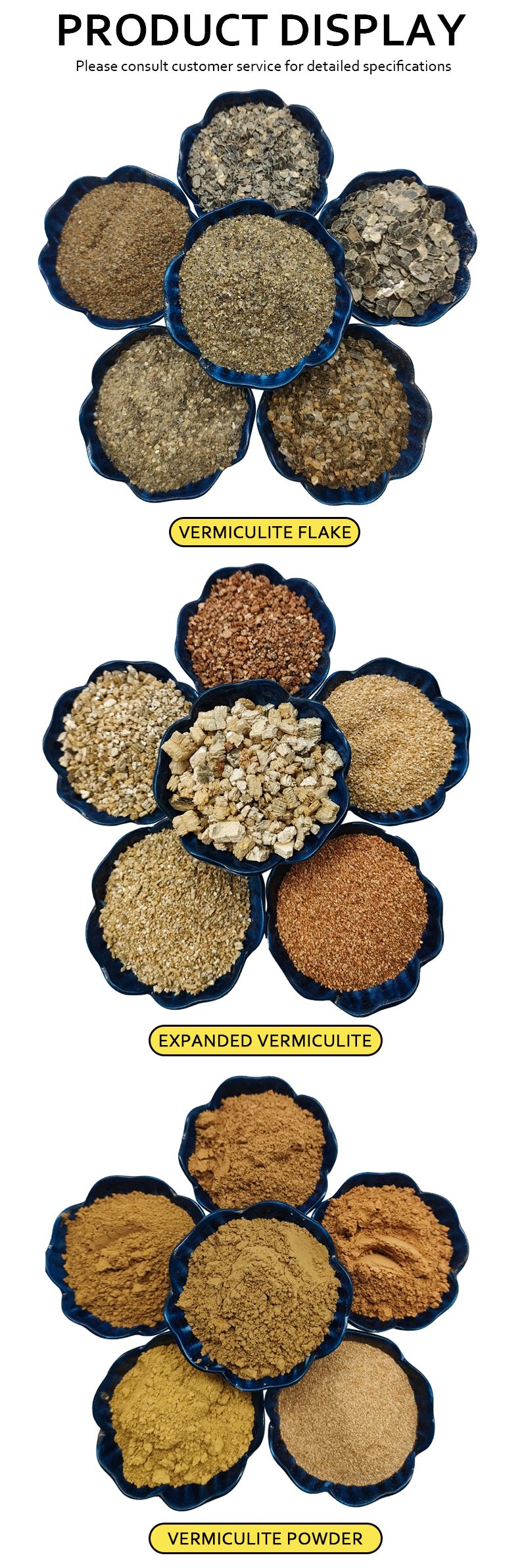

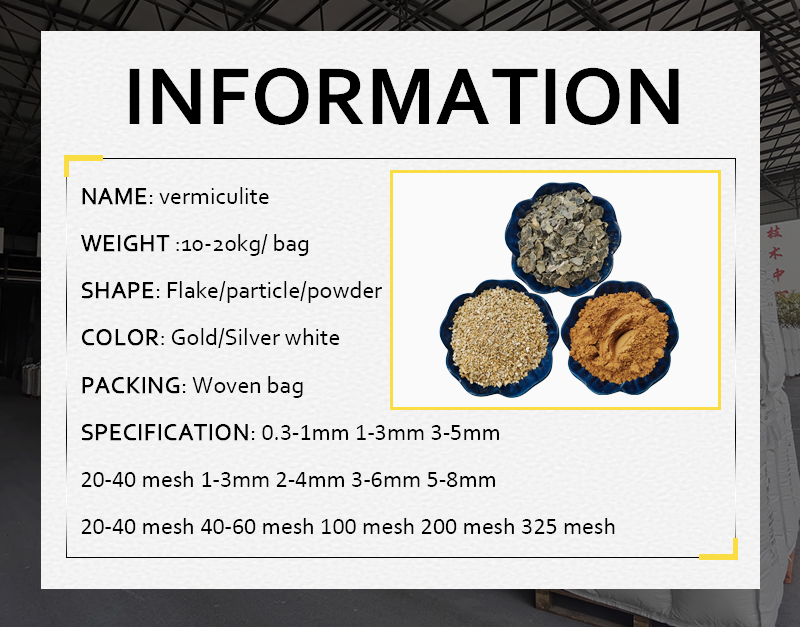

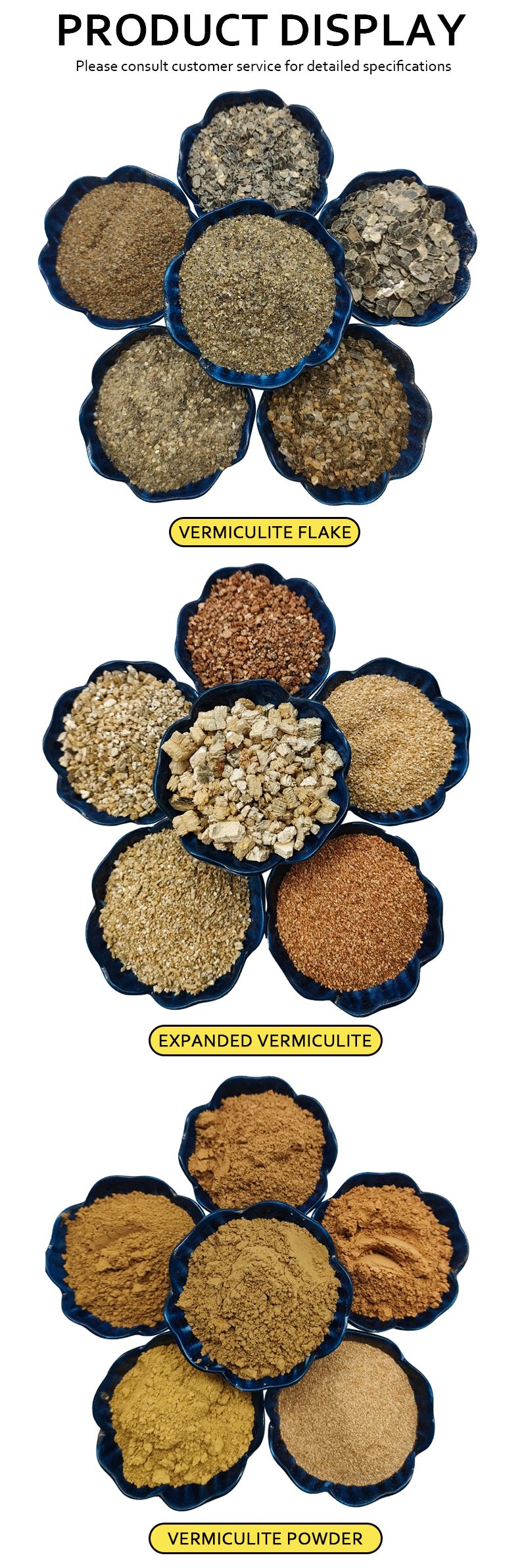

Processing of Vermiculite focuses on activating its natural layered traits and optimizing compatibility with target applications, with expansion as core and most critical step. Raw vermiculite ore, after sorting and crushing into small chunks, is heated at moderate temperatures in rotary kilns—this heat triggers evaporation of interlayer water, creating pressure that pries apart the layered structure. The result is lightweight, honeycomb-like porous material with dramatically enhanced thermal and sound insulation properties compared to raw ore. This expansion process not only boosts functionality but also preserves mineral’s inherent fire resistance, as it involves no chemical changes to vermiculite’s crystalline composition while increasing surface area for better performance. Post-expansion, Vermiculite is screened into precise particle size grades via multi-stage sieving, each grade tailored to specific uses: fine flakes (50-100 micrometers) for Thermal Insulation coatings and Sound Absorption panels, ensuring uniform coverage and seamless integration with binders; medium granules (100-500 micrometers) for Construction Material like lightweight mortar and Refractory Material such as fire bricks, balancing mechanical strength and porous insulation; and coarse particles (500 micrometers to 2 millimeters) for Packaging Cushion loose fill and plant pot liners, providing flexible shock absorption. Throughout processing, no toxic solvents, chemical activators, or synthetic additives are used—only physical crushing, heating, and screening—maintaining non-toxic nature suitable for both industrial settings (like factory insulation) and consumer-related applications (like household packaging).

Key processing adjustments vary by application to maximize Vermiculite’s performance, ensuring it integrates seamlessly with different production systems. For Refractory Material used in industrial furnaces, expanded Vermiculite undergoes additional controlled high-temperature annealing to further strengthen its crystalline structure, enhancing resistance to thermal shock and prolonged exposure to extreme heat. Flakes for Sound Absorption are processed into thin, flexible mats via bonding with natural, plant-based resins (such as soy-based adhesives), which maintain material’s porous structure while enabling easy installation on walls and ceilings. Granules for Construction Material are pre-treated with silane coupling agents—derived from natural sources—to improve adhesion with cement and concrete, preventing segregation and ensuring uniform distribution of insulation properties in lightweight mortars. Waste generated during processing, primarily fine Vermiculite dust from screening, is not discarded but collected and repurposed: it is mixed with water-based binders to form low-density Thermal Insulation sprays for hard-to-reach gaps in buildings and industrial equipment. Energy efficiency is prioritized throughout processing: heat recovery systems capture excess heat from expansion kilns to pre-heat raw ore, reducing overall energy consumption by significant margins, while solar-powered fans assist in air classification, lowering reliance on grid electricity.

Core properties of Vermiculite make it irreplaceable across target industries, with each trait directly addressing critical application challenges and outperforming alternative materials. Lightweight porous structure after expansion provides exceptional Thermal Insulation: it traps air within its honeycomb pores, creating natural barrier that reduces heat transfer—this makes it far more effective than traditional mineral wool in buildings, cutting energy consumption for heating and cooling. Inherent fire resistance, a result of its silica-rich composition, allows Vermiculite to withstand high temperatures without burning, melting, or releasing toxic fumes—unlike synthetic foam insulators that ignite easily, it is ideal for Fire Resistance materials that prevent flame spread in construction and industrial settings. Layered, porous structure also enhances Sound Absorption by trapping and dissipating sound waves, reducing echo and ambient noise more effectively than rigid foam in interior spaces. Flexibility of expanded Vermiculite flakes and granules ensures effective shock absorption in Packaging Cushion: unlike brittle polystyrene, it can absorb impact repeatedly without breaking, protecting fragile items like glassware, ceramics, and electronic components during transport. Additionally, Vermiculite’s chemical inertness ensures compatibility with diverse materials—from cement and resins to adhesives—preventing adverse reactions that could degrade end products, while its non-hygroscopic nature resists moisture absorption, maintaining performance in humid environments like coastal buildings or underground pipelines.

Architectural Insulation stands as flagship application for Vermiculite, addressing pressing building efficiency needs in both residential and industrial sectors. In residential and commercial buildings, expanded Vermiculite flakes are mixed into gypsum wall insulation boards and asphalt roof coatings—these products leverage its thermal insulation to reduce energy consumption for heating and cooling by substantial amounts, while its fire resistance adds an extra layer of safety. For high-rise buildings, Vermiculite-based exterior insulation finishing systems (EIFS) are applied to exterior walls, providing continuous insulation that eliminates thermal bridges and improves overall energy efficiency. In industrial settings, Vermiculite-based insulation wraps are used for hot fluid pipelines in chemical plants and power stations—its heat-resistant properties prevent heat loss from pipelines, boosting energy efficiency of industrial processes and reducing operational costs. Cold storage facilities, such as food warehouses and pharmaceutical storage units, rely on Vermiculite insulation in walls and floors: its low thermal conductivity maintains stable low temperatures inside, reducing refrigeration load and extending shelf life of stored goods. Even in historic building renovations, Vermiculite is preferred for insulation—it can be blown into narrow wall cavities without damaging original structures, preserving architectural heritage while improving energy performance.

Sound Absorption and Packaging Cushion applications highlight Vermiculite’s versatility, adapting to both comfort-focused and protective needs. In interior design, Vermiculite mats and panels are installed as wall and ceiling liners in noise-sensitive spaces: offices use them to reduce chatter and equipment noise, theaters and concert halls rely on them to optimize acoustics by controlling reverberation, and recording studios use high-density Vermiculite boards to achieve soundproofing that blocks external interference. These products outperform traditional fiberglass in sound absorption while being easier to handle and non-irritating. For Packaging Cushion, expanded Vermiculite granules serve as eco-friendly alternative to plastic foam: they are used as loose fill in shipping boxes for fragile items like handcrafted ceramics, artworks, and electronic devices, conforming to irregular shapes and absorbing impact during transport. Custom-molded Vermiculite cushions are also used for high-value items like laboratory glassware and antique artifacts, providing tailored protection. In transportation, Vermiculite is integrated into automotive interior components—door panels and floor mats use Vermiculite-reinforced foam to reduce road, engine, and wind noise, enhancing passenger comfort. Unlike synthetic sound absorbers and packaging materials, Vermiculite is reusable and biodegradable, aligning with growing demand for eco-friendly solutions.

Quality control of Vermiculite is rigorously tailored to specific applications, ensuring consistent performance and reliability across batches. For Thermal Insulation products, key tests include thermal conductivity measurement using standardized heat transfer apparatus to verify heat resistance, and bulk density analysis to confirm lightweight properties—only batches meeting strict conductivity and density thresholds are approved for use. For Fire Resistance applications, tests are conducted in controlled combustion chambers: samples are exposed to standardized flame temperatures for specified durations to measure fire rating (resistance to flame spread and heat penetration) and smoke emission, ensuring no toxic fumes are released. For Sound Absorption, tests are performed in acoustic chambers to measure sound absorption coefficient across different frequencies, ensuring consistency in noise reduction performance. For Packaging Cushion, compression and impact tests simulate real-world transport conditions—samples are subjected to repeated impacts and pressure to verify shock absorption capacity and durability. All processed Vermiculite batches undergo thorough purity checks: magnetic separation removes iron impurities, and optical sorting eliminates residual quartz or mica, ensuring only pure Vermiculite enters production. For high-purity applications like construction mortar, additional chemical analysis confirms absence of harmful substances, while particle size distribution is verified via laser diffraction to ensure uniform dispersion in end products.

×

×