×

×

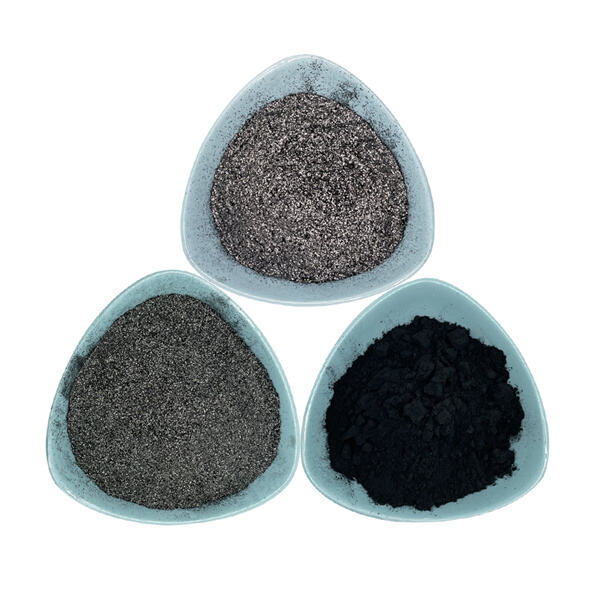

Find the Advantages of Fine Graphite Powder:

Graphite is a type of mineral often used in a variety of industries, including production, aerospace, and electronics. Fine graphite powder, in particular, is becoming well-known in the past few years because of its properties which can be unique. We will explore the benefits, innovation, security, use, how to use, solution, quality, and application of fine graphite powder created through DERUNHUABANG.

One of several main advantages of fine graphite powder is being able to perform electrical energy as well as heat. This DERUNHUABANG artificial graphite powder makes it well suited for use in electronic devices, such as smartphones, laptop computers, and pills. During the time and its same additionally it is extremely durable and will resist high conditions and pressure. This durability and strength ensure it is valuable to be used in machinery and other resources.

Present innovations in graphite powder have and expanded its usage potential beyond electronics and equipment. Graphite is currently progressively utilized in green technologies like batteries and power and renewable. Indeed, DERUNHUABANG carbon graphite powder is fast learning to be an element key of battery packs, which are commonly used in electric vehicles.

Thankfully, fine graphite powder of DERUNHUABANG is typically considered safe to use, since it is non-reactive and non-toxic. But, because of finely form powdered it is vital to take the required safety measures along with it. People must use gear protective as gloves, goggles, and masks to avoid inhalation of graphite dirt particles.

The use of DERUNHUABANG fine graphite powder are wide ranging, from lubrication to casting to drawing. Whenever graphite and its making use of, it is crucial to use in moderation and proceed with the item instructions to avoid any health problems. Additionally, the expanded graphite powder must certainly be held within a dry and destination and it is cool far from dampness.

As reputable mineral products supplier, have excellent teams that focus the design development products, quality control Fine graphite powder as well company management. Contact us you have any thoughts or suggestions about our products. look forward to collaborating with you and providing with high-quality products.

Shijiazhuang Huabang Mineral Products Co., Ltd. is a building materials enterprise integrating manufacturing, processing and sales. company situated in Shikan Industrial Zone, Ciyu Town, Lingshou County, Hebei Province 50km away from Shijiazhuang, capital Hebei Province, 260km away Beijing and has easy transportation, Fine graphite powder, vast mineral resources.

products have been certified ISO 9001 technical qualification certification are shipped to more than 70 countries, with more than 1,000 buyers Southeast Asia, Eastern Europe, America... products have been certified by ISO 9001 technical qualification Fine graphite powder have been exported to over 70 countries, more than 1000 customers and regions throughout Southeast Asia, Eastern Europe America...

Huayang provides plenty non-metal mineral products, as products, such as Fine graphite powder, mica, bentonite, graphite, tourmaline, iron oxide so. our province is in all kinds of mineral sources, quilted producing, processing, laboratory, storage workshop, production line over 20.

The grade of fine graphite powder is vital for the efficient use. The DERUNHUABANG high purity graphite powder most readily useful should have a frequent particle size, high purity amounts, and reasonable ash content. Whenever choosing graphite powder, it is vital to take note of these facets and consider purchasing from the provider reputable. Additionally, customer support can also be crucial, as clients require assistance and guidance when working with special materials are their particular businesses.

Finally, fine graphite powder created from DERUNHUABANG has an extensive range of programs, including aerospace, automotive, metallurgy, and much more. Used like a lubricant, natural graphite powder can help to reduce rubbing and use in equipment, also as being an element in higher level composites, conductive coatings, as well as other programs into the technology industry.