Iron oxide pigments emerge as versatile eco-friendly coloring materials that bridge sustainable development and circular economy, adapting innovatively to diverse demands of green architecture, road marking, and plastic coloring. Unlike synthetic pigments relying on toxic chemical synthesis or emitting harmful byproducts during production, iron oxide pigments originate from natural iron ore deposits or eco-friendly synthetic processes using industrial waste. This unique origin endows them with inherent color stability and exceptional weather resistance, traits that distinguish them from conventional coloring agents. Serving as core component in industrial coatings, concrete coloring, and interior decoration, iron oxide pigments transcend single-function roles to become multi-purpose solutions blending natural properties, functional performance, and environmental responsibility.

Resource foundation of iron oxide pigments combines natural abundance and circular economy principles. Natural iron oxide pigments are extracted from iron ore deposits rich in hematite (for red hues) and goethite (for yellow hues), distributed across continents—from Australian iron-rich mines to European sedimentary deposits. Synthetic iron oxide pigments are produced via controlled chemical reactions using iron-rich byproducts from steel manufacturing and metal processing, turning waste into valuable materials. Extraction and production adhere to strict eco-friendly standards: natural mining adopts surface extraction to avoid deep geological disturbance, and mined areas undergo vegetation restoration with native plants; synthetic processes use closed-loop systems to capture emissions and recycle wastewater, minimizing environmental impact. Circular economy is further practiced in waste reuse: pigment production residues are recycled as iron supplements in concrete, closing resource loops.

Production processes of iron oxide pigments focus on preserving core properties and reducing carbon footprint. Natural pigments undergo physical processing: ore crushing, fine grinding, and multi-stage sieving to separate pigment particles from impurities, with no toxic chemicals involved—this retains natural color depth and stability. Synthetic pigments use low-temperature chemical reactions (avoiding high-energy heating) to control particle size and color shade, ensuring consistency across batches. Post-production treatment includes eco-friendly surface modification: some pigments are coated with natural silicates to enhance dispersion in water-based coatings and plastics, improving coloring uniformity without adding harmful additives. Solar-powered drying systems replace fossil fuel heating in final processing, cutting carbon emissions significantly. These processes retain iron oxide pigments’ key traits while optimizing compatibility with diverse substrates.

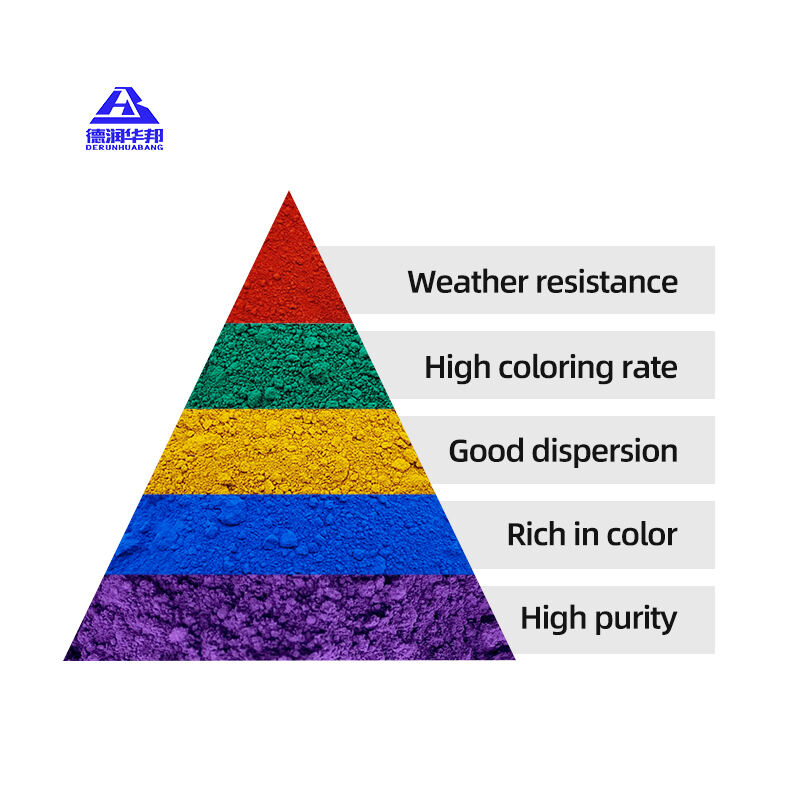

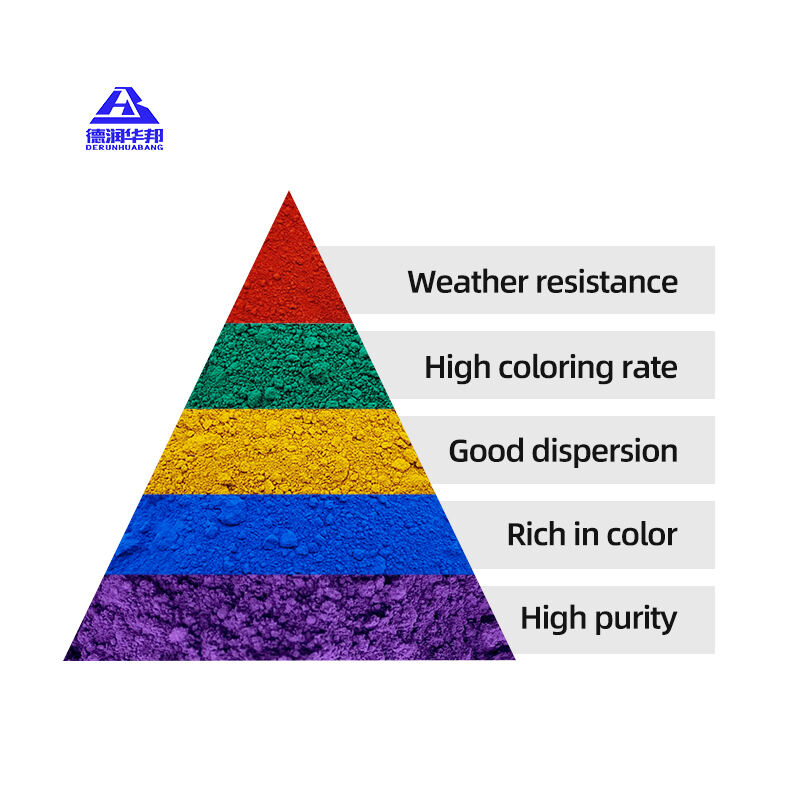

Core properties of iron oxide pigments make them irreplaceable across industries. Color stability ensures long-lasting hue retention: they resist fading caused by ultraviolet radiation, rain, and temperature fluctuations, maintaining consistent appearance in outdoor structures and indoor spaces for years. Weather resistance allows use in harsh environments—from coastal buildings exposed to salt spray to desert roads under intense sunlight—without degradation. Chemical inertness ensures compatibility with concrete, coatings, plastics, and ceramics, avoiding reactions that alter color or material integrity. Non-toxic nature makes them suitable for interior spaces and plastic products, as they release no volatile organic compounds. Wide color spectrum—covering red, yellow, black, brown, and blended earth tones—meets diverse aesthetic and functional needs in construction and industrial sectors.

Iron oxide pigments excel in diverse innovative application scenarios. Green architecture leverages their weather resistance and color stability: added to exterior wall panels and roof tiles, they provide long-lasting color that reduces repainting frequency, lowering maintenance costs and waste. Road marking is a key new application: iron oxide pigments with high light reflectivity are mixed into road paints, enhancing visibility of traffic lines in rain and low light—their weather resistance ensures markings remain clear for years. Industrial coatings use them to color metal structures like pipelines and storage tanks: pigments form protective layer that resists corrosion and UV damage, extending service life. Concrete coloring applies them to decorative pavements, park benches, and building facades—pigments penetrate concrete surfaces, creating permanent, wear-resistant color that avoids peeling (unlike surface paints). Plastic coloring uses them in products like garden furniture and children’s play equipment: non-toxic pigments provide vibrant, fade-resistant color while meeting safety standards. Interior decoration integrates them into wall paints and ceramic tiles—earthy red and brown hues complement rustic designs, while yellow tones add warmth to modern spaces.

Quality control of iron oxide pigments is tailored to specific applications. For road marking, light reflectivity tests measure visibility under simulated rain and low light, while wear resistance tests ensure markings withstand vehicle traffic. For architectural coatings, color fastness tests expose pigments to simulated sunlight and salt spray for extended periods to verify fading resistance. For plastics, heat stability tests confirm color retention during plastic processing temperatures. For interior use, toxicology tests ensure compliance with non-toxic standards. Both natural and synthetic pigments undergo particle size analysis to ensure uniform dispersion, preventing color streaks in end products. Recycled pigment waste (from production trimmings) undergoes purification and performance testing to match virgin pigment standards, ensuring reliable reuse.

In conclusion, iron oxide pigments stand as cornerstone eco-friendly coloring materials aligning with sustainable development and circular economy. Their natural or waste-derived origin and eco-friendly production preserve core traits of color stability and weather resistance—traits driving value in green architecture, road marking, industrial coatings, and interior decoration. Unlike toxic synthetic pigments that harm ecosystems and human health, iron oxide pigments’ lifecycle minimizes environmental impact from production to waste reuse. Innovative applications demonstrate their adaptability: enhancing infrastructure durability, improving road safety, and creating healthy, aesthetically pleasing spaces. As demand for eco-friendly, long-lasting coloring materials grows, iron oxide pigments will remain vital choice, connecting natural resources and industrial innovation in sustainable ways.

×

×