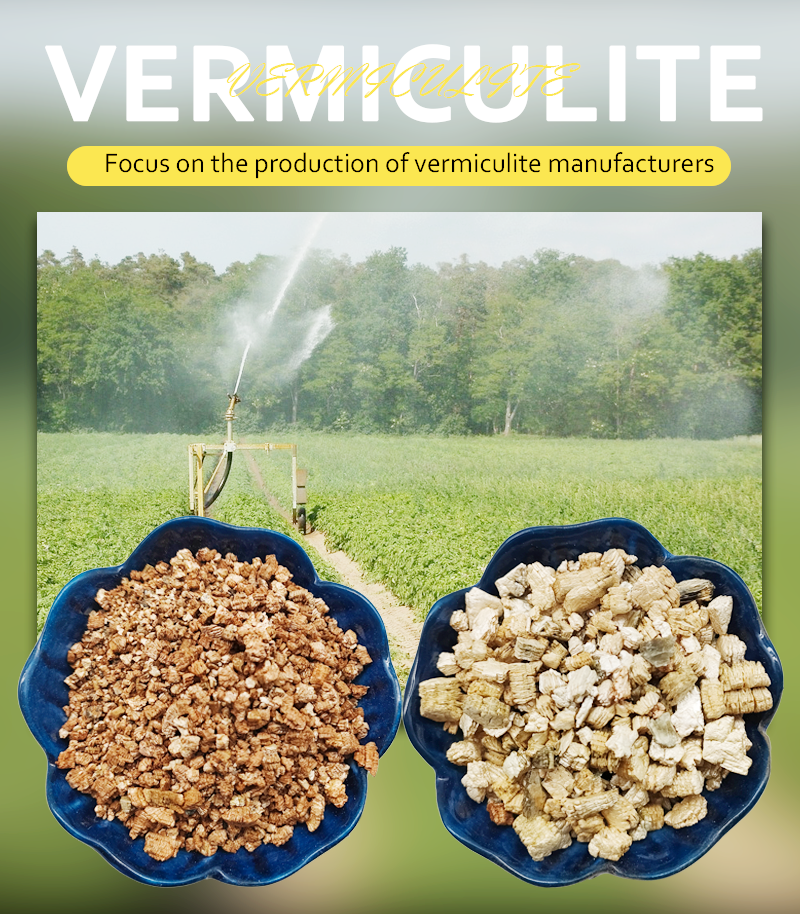

Vermiculite emerges as versatile mineral material that caters to diverse demands of Material Innovation, Industrial Casting, and Thermal Insulation Mortar. Unlike single-function mineral additives such as perlite or diatomite—limited by narrow performance like perlite’s weak refractory ability or diatomite’s poor mechanical strength—Vermiculite exhibits unique combination of physical traits: layered crystalline structure, lightweight porous texture after expansion, and excellent thermal stability. These traits enhance functionality of end products across industries, from casting to construction. Derived from natural vermiculite ore deposits formed via hydrothermal alteration, Vermiculite undergoes physical processing without toxic chemicals, aligning with modern trends focused on durability and application flexibility. Serving as core component in Sound Insulation Board, Packaging Buffer, and Casting Sand Additive, Vermiculite transcends ordinary mineral status to become multi-purpose solution blending structural support, functional efficiency, and cost-effectiveness.

Resource foundation of Vermiculite combines natural abundance and regional trait diversity, with ore properties tailored to specific application needs. Natural vermiculite ore forms in distinct geological settings worldwide: Brazilian vermiculite deposits produce ore with high expansion ratio and low impurity content, ideal for Industrial Casting and Casting Sand Additive; Indian vermiculite ore yields layers with strong flexibility, perfect for Sound Insulation Board and Packaging Buffer; Australian vermiculite deposits offer dense layered structure, suited for Thermal Insulation Mortar and Refractory Auxiliary. Mining of vermiculite ore adheres to selective surface extraction to avoid deep geological disruption, and ore sorting relies on physical screening to separate vermiculite layers from associated minerals like mica and quartz, preserving inherent layered structure critical for expansion and performance.

Processing of Vermiculite focuses on activating natural traits and optimizing compatibility with target applications. Core processing step is expansion: raw vermiculite ore is first dried to reduce moisture, then heated at moderate temperatures to expand its layered structure into lightweight, honeycomb-like particles. This expansion amplifies thermal insulation and sound absorption properties while retaining refractory ability. Post-expansion, Vermiculite is screened into precise grades: fine flakes for Construction Coating and Sound Insulation Board, ensuring uniform dispersion; medium granules for Thermal Insulation Mortar and Casting Sand Additive, balancing strength and porosity; coarse particles for Packaging Buffer and Lightweight Aggregate, providing flexible support. No toxic solvents are used, maintaining non-toxic nature suitable for industrial and consumer-related applications.

Key processing adjustments vary by application: Vermiculite for Refractory Auxiliary undergoes additional heat treatment to enhance high-temperature resistance; flakes for Sound Insulation Board are bonded with plant-based resins to form flexible mats; granules for Casting Sand Additive are mixed with clay to improve adhesion. Waste from processing—fine vermiculite dust—is collected and repurposed into low-density Thermal Insulation Mortar, ensuring material efficiency. Energy efficiency is prioritized via heat recovery from expansion furnaces to pre-heat raw ore, reducing overall energy consumption.

In Industrial Casting, Vermiculite serves as critical Casting Sand Additive and refractory auxiliary. Mixed into casting sand, its porous structure improves sand permeability, allowing gas to escape during metal pouring and reducing defects like pores in cast parts. As refractory auxiliary in casting molds, it resists high temperatures from molten metal, preventing mold deformation and ensuring cast part precision. Automobile and machinery manufacturers rely on this application to produce high-quality engine parts and structural components, as it enhances casting consistency and reduces rework rates.

Thermal Insulation Mortar and Construction Coating leverage Vermiculite’s insulation properties. Mixed into mortar for building interiors and exteriors, its lightweight porous structure traps air, forming effective thermal barrier that reduces heating and cooling costs. In Construction Coating for industrial warehouses and residential walls, fine vermiculite flakes disperse evenly to create thin, insulating layers that resist cracking and peeling. Unlike synthetic insulation additives, it maintains performance in humid environments, making it suitable for coastal and high-humidity regions.

Sound Insulation Board and Packaging Buffer highlight Vermiculite’s versatility. Vermiculite-based Sound Insulation Board is installed in commercial spaces like offices and shopping malls—its layered structure traps sound waves, reducing ambient noise and echo. For Packaging Buffer, expanded vermiculite granules act as eco-friendly alternative to plastic foam, conforming to irregular shapes of fragile items like glassware and electronic components. Its flexibility absorbs impact during transport, and it is reusable or biodegradable, avoiding plastic waste.

Quality control is tailored to applications: for Casting Sand Additive, tests measure permeability and heat resistance to ensure casting quality; for Thermal Insulation Mortar, thermal conductivity tests verify insulation performance; for Sound Insulation Board, acoustic tests measure noise reduction ability; for Packaging Buffer, impact tests simulate transport conditions. All batches undergo purity checks to remove impurities, and particle size is verified via screening to ensure consistency.

In conclusion, Vermiculite stands as cornerstone mineral material driving innovation in Material Innovation, Industrial Casting, and construction sectors. Its natural origin, simple processing, and traits—thermal insulation, refractory ability, sound absorption—deliver unique value in Casting Sand Additive, Thermal Insulation Mortar, Sound Insulation Board, and Packaging Buffer. Unlike synthetic materials with complex production, it offers cost-effective, long-lasting performance. As demand for efficient, eco-friendly industrial materials grows.

×

×